Related product categories

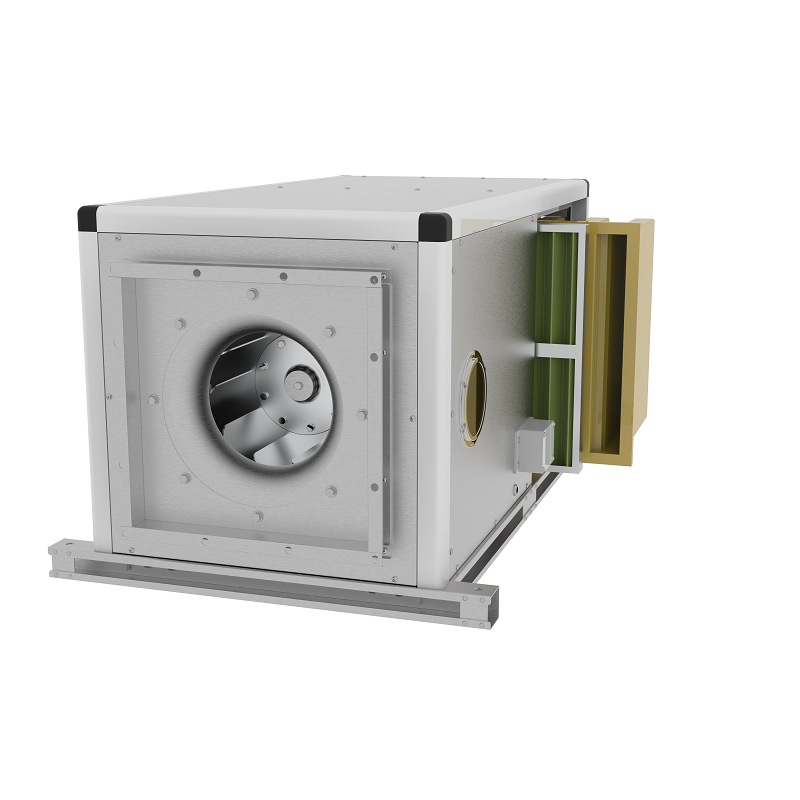

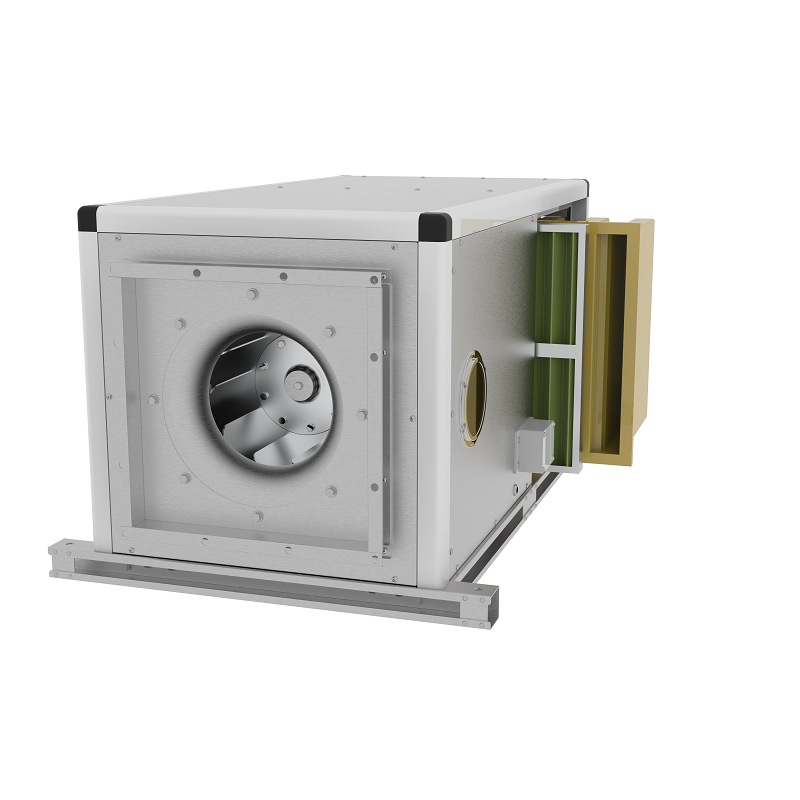

Our company's independently developed EF series air purification dedicated fan case integrates more than ten years of technological accumulation and precipitation, with multiple technological advantages. The overall performance of the fan is industry-leading, and its uniqueness is the first of its kind in China.

The EF series air purification dedicated fan case adopts our patented box structure, which not only strengthens the strength of the unit itself, but also solves the problems of air leakage, strength, and consistency; It has the characteristics of compact structure, beautiful appearance, easy installation and maintenance, strong rigidity of the whole machine, and low air leakage rate. The application of interlocking technology inside the box makes assembly simple and convenient; The special concave convex groove design makes it easy to achieve scientific combination between the wall panels; The adoption of in board strengthening technology results in a continuous and smooth surface of the unit, with a clear and smooth appearance and higher mechanical strength.

The EF series air purification dedicated fan case is equipped with advanced technology and research results such as self-developed product automation selection design software, box airflow organization simulation design software CFD/CAE computer simulation technology, etc. It has comprehensively optimized and upgraded the EF series air purification dedicated fan case, greatly improving the performance and quality of the product, and providing more cost-effective fan products for the air treatment and purification industry. It can be matched according to customer requirements to obtain more suitable selection.

This series of products is widely used in industrial fans such as electronic instruments, precision machinery manufacturing, textiles, cigarettes, pharmaceuticals, hospitals, food, power plants, light industry, rail transit, and aerospace. It is also suitable for comfort fans in commercial buildings, supermarkets, cinemas, hotels, and office buildings, as well as large and medium-sized commercial and civil public buildings.

The air volume of this series of units ranges from 200 to 300000mm ³/h, with 36 standard specifications to choose from. Different functional segments can be configured according to customer needs. In addition to the basic functional segments available for selection, optional segments can also be provided according to customer needs: initial effect new return air segment, fan segment, noise reduction segment, medium efficiency filtration segment, sterilization segment, and high-efficiency filtration segment.

1. The motor adopts a high-efficiency EC motor. No position sensor is required. It can implement sine wave stepless speed regulation according to external signals, and its performance is stable. Powerful and stable protection function for soft and hard facilities. Optional industrial standard serial number, industrial Internet remote monitoring. Prevention. Energy saving more than 30% than traditional AC motors.

2. EC fan can maintain high efficiency operation even with changes in air volume and load. Due to the characteristics of EC's continuously variable speed EC fans can operate at any speed with external control signals. Compared to AC fans, they have significant advantages in efficiency. Within an uninterrupted control range, the energy-saving effect is significantly improved both directly and indirectly. If we consider the additional hardware costs and operational losses caused by the variable frequency operation of AC fans, such as frequency converters The efficiency advantage of EC fans is more significant.

3. The advantage of stepless speed regulation of EC purification fan is that it can achieve high efficiency filtration in junior high schools. However, if there is blockage during long-term operation, the exhaust effect will be reduced. The fan is equipped with differential pressure sensing, which can implement automatic speed regulation function to ensure the long-term exhaust effect of the fan and increase the use time of the filter.

4. Optional differential pressure alarm function. When the filter reaches a certain level of blockage, the fan will start the automatic alarm function to prompt the owner to replace the filter and ensure the ventilation volume of the exhaust air.

5. The effect of intelligent sterilization lamp can be configured first, and the sterilization lamp can be set to start or close in advance, so that the exhaust fan can be started in advance, and the residual bacteria can be disinfection and sterilization in advance when the fan stays. The Ting Shi shutdown function can effectively disinfect the bacteria and cold water accumulated in the filtered air after ventilation. Reduce bacterial growth in the filter.

(1) Adopting self-developed sixth generation impellers to achieve drag reduction and noise reduction technology, which is in line with the optimal tooth profile combination for this type of fan. The number of teeth, tooth height, tooth width, and the gradual combination of teeth are key factors affecting the efficiency and noise of the fan. The acoustic comparison test results reveal that biomimetic serrations are beneficial in preventing the formation of shedding vortices on the blade surface due to turbulent boundary layer, and have a certain effect on noise reduction and sound quality improvement of the fan. Effectively reduces high-frequency eddy current noise, achieves high-precision balance of the impeller, and can control the overall vibration value between G1.0-G2.0 according to international standard G2.5.

(2) Motor brand: When the fan is used for conventional civil or industrial ventilation, different well-known motor brands can be selected according to customer requirements.

(3) Maintenance door: The fan is equipped with a large-sized maintenance door that can be freely removed as a whole. The maintenance door must be fastened on the inside of the box, and the insulation material must be used to seal between the maintenance door and the box frame. The maintenance door must be equipped with a high-strength fire-resistant handle, and the fixing method of the maintenance door is lock locking (cannot be fixed with bolts or self tapping screws). The lock locking foot must be matched on the aluminum alloy profile frame and locked with bolts. Each maintenance door must be equipped with more than 4 sets of locks, and the outer packaging material of the lock on the maintenance door must be fire-resistant engineering plastic.

(4) Wind outlet flange: Both the inlet and outlet are equipped with connecting flanges, which are made of aluminum alloy or galvanized sheet material to facilitate soft connection with the air duct and ensure a long service life in humid environments. (5) The snail shell free fan is equipped with a direct connected motor, which eliminates belt debris generated by belt transmission and is particularly suitable for clean systems.

(6) The fan is equipped with a 6P outdoor waterproof terminal junction box, which is convenient for customers to install and wire, suitable for various environments and outdoor use.

(7) Stainless steel observation window, made of 5MM thick tempered glass, achieves high strength compression performance and can withstand more than 200 degrees of high temperature. The observation window is placed at the position of the impeller, which is convenient for customers to debug the positive and negative rotation of the fan after installation and wiring, and the use of the impeller!

(8) Accurate computer selection ensures precise matching.

(1) Adopting internationally renowned brand motors and frequency converters, with high efficiency, low vibration, good heat dissipation, stable and reliable performance.

(2) Non electromagnetic frequency converters can be used to prevent high-frequency electromagnetic noise from the motor in spaces with special requirements for high silence.

(3) The snail shell free fan is equipped with a direct connected motor, which does not require belt transmission, has high efficiency, low noise, and no belt debris pollution problem.

(4) The frequency converter can be installed separately in the unit casing for convenient daily operation, and a motor with a built-in frequency converter can also be optionally selected.

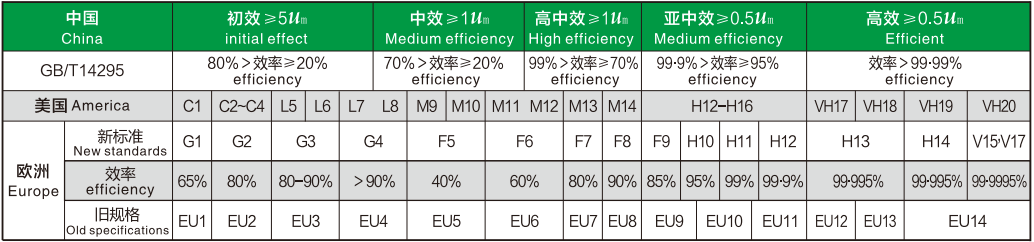

(1) We use air filtration products from well-known domestic and foreign brands.

(2) Using CFD simulation technology, optimize the installation structure of the filter to ensure optimal filtration effect.

(3) All specifications of filters can choose antibacterial products containing high-efficiency antibacterial agents.

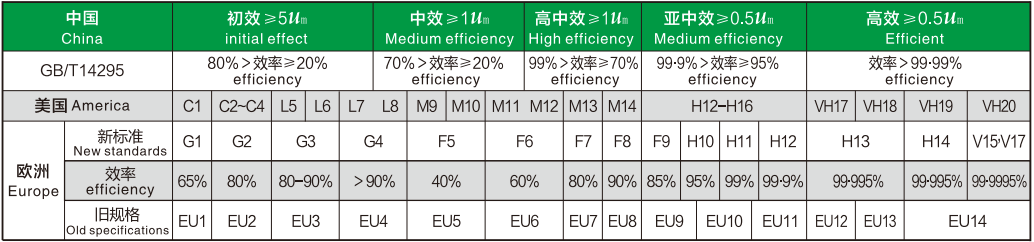

● Plate type initial efficiency filter

The filter material is a synthetic fiber woven from imported polyamide monofilament fibers, designed with multiple pleats, with a filtration efficiency of G3~G4 and an initial resistance of less than 70Pa; Adopting high-strength and moisture resistant paper frame, the structure is lightweight, the price is affordable, and the maintenance cost is low; Suitable for one-time disposal and meets the environmental requirements of clean operating room construction standards.

● Bag type medium efficiency filter

Adopting new composite non-woven fabric or imported synthetic fiber filter media, the filtration efficiency can be selected from F5 to F8; Large filtration area, low frontal wind speed, large dust holding capacity, initial resistance less than 150Pa; Adopting ultrasonic welding technology, it has good airtightness and stable performance; Equipped with various metal frames such as galvanized sheet and aluminum alloy, it has high structural strength, long service life, and can be repeatedly cleaned and used.

● Dense pleated sub high efficiency filter

The filtering material is glass fiber filter paper or ultrafine polypropylene filter paper, and the filtering efficiency can be selected from H9~H13. The filtering area is large, the resistance is small, and the initial resistance is less than 400Pa; The outer frame is made of high-strength environmentally friendly plastic and sealed with a new type of polyurethane sealant; The overall environmental protection is incineratable, non-toxic and odorless, easy to dispose of, and meets the environmental requirements of clean operating room construction standards.

|  |  |  |  |

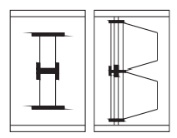

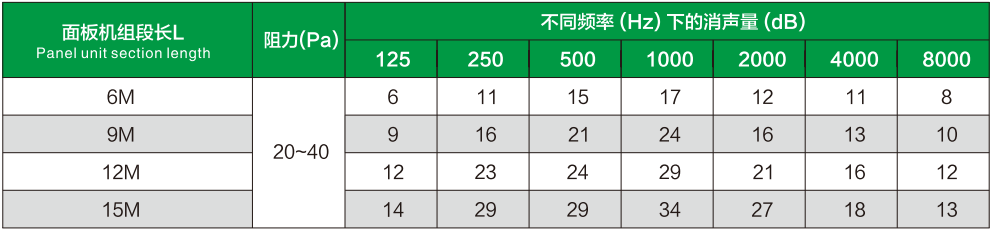

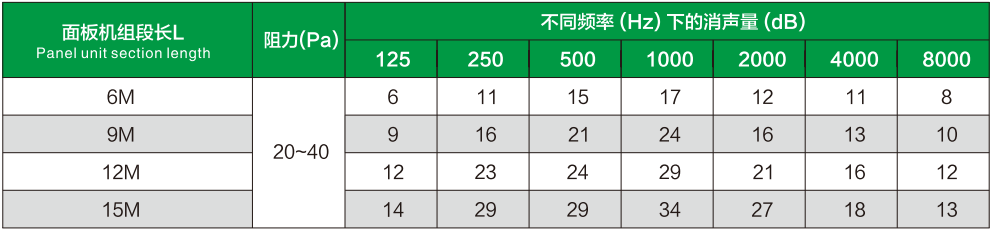

Silencers can be divided into inlet and outlet silencers. They can be equipped with impedance composite silencers or metal microporous plate silencers, which can be configured according to different noise requirements.

PLC (Programmable Logic Controller) can be used to achieve fully automatic control, with high reliability, convenient use, powerful functions, easy maintenance, and easy expansion of external connections. It can reserve interfaces and communication protocols to connect with BAS (Building Automation System) for remote control. The operation display of the unit configuration adopts full Chinese display, which is simple and easy to use. PLC can achieve on/off control of the unit, interlock control of the fan, various protective measures (such as fan motor overload, insufficient air, filter blockage, etc.) and fault alarms, PID control, and timed on/off control. The operating parameters of the unit can be modified on-site, and triple password protection is configured to prevent misoperation and malicious operation, ensuring security.

(1) The sterilization section can be equipped with ultraviolet lamps (UV), ozone generators (0 *), activated carbon filters, nano photocatalysts (TiO.+UV), and enzyme sterilization accessories to effectively kill bacteria in the circulating air.

(2) UV sterilization lamps can be used before the filter, which can effectively kill bacteria in the circulating air and on the filter. At the same time, they are linked with the fan and equipped with electronic switches or limit switches on the unit door panel, which can effectively prevent UV light from harming operators.

(3) Customers can also choose sterilization and disinfection accessories such as ozone generators, electronic filters, activated carbon filters, nano photocatalysts, and biological enzyme sterilization according to their needs.

| (1) Primary filter, divided into plate type and bag type, plate type primary filter adopts multi-layer aluminum alloy wire mesh or chemical fiber material; The initial effect of the bag is made of non-woven fabric or special synthetic fiber, which has the advantages of water resistance, low resistance, and stable performance. The initial filtration level can reach G4. (2) Medium efficiency filter, divided into plate and bag types, using ultra-fine chemical fiber or glass fiber filter material, with the characteristics of long service life and stable performance. The medium efficiency filtration level can reach F8. (3) High efficiency and sub high efficiency filters use ultra-fine synthetic fiber or glass fiber filter materials, with dense pleated and bag type options available. The high and sub high efficiency filtration levels can reach H13. (4) Chemical filters and photocatalysts mainly remove chemical pollutants from the air. There are activated carbon cylinders available for selection. |

| According to different usage requirements and the characteristics of fan noise, the sound-absorbing section can use microporous plate mufflers or perforated plates with built-in sound-absorbing cotton. When air passes through perforated panels with built-in sound-absorbing cotton, it has a good sound-absorbing effect on medium and high-frequency noise. The interior of the microporous plate muffler is a cavity, and the frame is made of perforated galvanized steel plate, lined with ultra-fine glass wool and wrapped with glass fiber cloth. It uses the principle of resonance sound absorption in physics to absorb sound waves, and has the advantages of non pollution and moisture resistance. It has an effective sound-absorbing effect on low-frequency and mid frequency noise. The silencing section is divided into return air silencing and supply air silencing. |

(1) The unit adopts a dual inlet centrifugal fan, which has three forms: forward leaning, backward leaning, and wing shaped.

(2) The fan impeller is dynamically and statically balanced according to the air volume and speed.

(3) The fan and motor are assembled on the same frame, and shock absorbers are used for isolation.

(4) The motor adopts a three-phase asynchronous motor with good insulation properties.

(5) The fan section has maintenance doors and power holes, which facilitate user maintenance and power connection.

(6) Variable speed motors can be selected according to customer requirements.

(7) The motor can be selected with other voltages and frequencies according to customer requirements.

(8) The air supply methods of the fan section are divided into

(1) The technical parameters listed in the sample are all standard units, which can be designed according to the actual requirements of the project in practical engineering. When customers place orders, they should provide the design parameters of the equipment, such as air volume, unit total pressure, inlet and outlet air parameters, cleanliness requirements, etc.

(2) If the customer needs a more detailed understanding of the fan parameters, please notify our company to provide the characteristic curve of the fan separately.

(3) Our company can adjust the form and size of the air outlet according to actual requirements.

(4) Due to the flexible combination of various functional segments, if customers need detailed information on the total weight of the machine, please notify our company to provide the weight of the unit separately.

(5) Please feel free to contact Horsepower Company for any other specific requirements in actual engineering.

On site installation should be carried out under the guidance of professional technicians who are familiar with and trained on this product. During installation, the following points should be noted:

(1) Before installation, please check whether the model and quantity of each accessory on the packing list are correct.

(2) A set of assembly drawings is randomly attached to the unit, and installation should strictly follow the drawings provided by the horsepower company.

(3) During the installation of the unit, debris inside the unit should be promptly removed,

(4) When installing the unit, there should be space available for each functional section to function.

(5) Check the lubrication condition of each rotating component and whether each adjusting device is flexible.

(6) The unit shall not bear the weight of external pipelines and air ducts.

(7) Flexible connections should be used between the dedicated air purification fan box and the external air duct to avoid the transmission of vibration.

(8) The connections between unit sections and between box boards must be tight.

(9) If there is a sealing rubber strip, it must be tightly pressed to prevent air leakage.

(10) The air filter should be installed after other components of the unit have been installed, and the filter material of the air filter should be checked for damage or contamination before installation.

The installation of pipeline systems should comply with local regulations. Pipelines should be designed to minimize bending and vertical displacement as much as possible to save costs and maintain optimal unit performance. The pipeline must be insulated.

The correct installation should include the following points:

(1) Pipelines should be equipped with shock absorbers. Reduce vibration and prevent pipeline loosening and air leakage.

(2) Maintenance valves should be installed on pipelines. It can be opened and closed during maintenance to isolate the unit from the pipeline system.

(3) The pipeline system should be equipped with air volume control valves, static pressure boxes, etc., and silencers should be installed in environments with specific requirements for low noise.

(4) If the fan is installed in a mezzanine, sufficient maintenance space and access ports must be reserved.

(5) The dedicated air purification fan box and external air duct should not have bends, diameter changes, or misalignment installation within a distance of twice the impeller diameter of the fan.

Our company's independently developed EF series air purification dedicated fan case integrates more than ten years of technological accumulation and precipitation, with multiple technological advantages. The overall performance of the fan is industry-leading, and its uniqueness is the first of its kind in China.

The EF series air purification dedicated fan case adopts our patented box structure, which not only strengthens the strength of the unit itself, but also solves the problems of air leakage, strength, and consistency; It has the characteristics of compact structure, beautiful appearance, easy installation and maintenance, strong rigidity of the whole machine, and low air leakage rate. The application of interlocking technology inside the box makes assembly simple and convenient; The special concave convex groove design makes it easy to achieve scientific combination between the wall panels; The adoption of in board strengthening technology results in a continuous and smooth surface of the unit, with a clear and smooth appearance and higher mechanical strength.

The EF series air purification dedicated fan case is equipped with advanced technology and research results such as self-developed product automation selection design software, box airflow organization simulation design software CFD/CAE computer simulation technology, etc. It has comprehensively optimized and upgraded the EF series air purification dedicated fan case, greatly improving the performance and quality of the product, and providing more cost-effective fan products for the air treatment and purification industry. It can be matched according to customer requirements to obtain more suitable selection.

This series of products is widely used in industrial fans such as electronic instruments, precision machinery manufacturing, textiles, cigarettes, pharmaceuticals, hospitals, food, power plants, light industry, rail transit, and aerospace. It is also suitable for comfort fans in commercial buildings, supermarkets, cinemas, hotels, and office buildings, as well as large and medium-sized commercial and civil public buildings.

The air volume of this series of units ranges from 200 to 300000mm ³/h, with 36 standard specifications to choose from. Different functional segments can be configured according to customer needs. In addition to the basic functional segments available for selection, optional segments can also be provided according to customer needs: initial effect new return air segment, fan segment, noise reduction segment, medium efficiency filtration segment, sterilization segment, and high-efficiency filtration segment.

1. The motor adopts a high-efficiency EC motor. No position sensor is required. It can implement sine wave stepless speed regulation according to external signals, and its performance is stable. Powerful and stable protection function for soft and hard facilities. Optional industrial standard serial number, industrial Internet remote monitoring. Prevention. Energy saving more than 30% than traditional AC motors.

2. EC fan can maintain high efficiency operation even with changes in air volume and load. Due to the characteristics of EC's continuously variable speed EC fans can operate at any speed with external control signals. Compared to AC fans, they have significant advantages in efficiency. Within an uninterrupted control range, the energy-saving effect is significantly improved both directly and indirectly. If we consider the additional hardware costs and operational losses caused by the variable frequency operation of AC fans, such as frequency converters The efficiency advantage of EC fans is more significant.

3. The advantage of stepless speed regulation of EC purification fan is that it can achieve high efficiency filtration in junior high schools. However, if there is blockage during long-term operation, the exhaust effect will be reduced. The fan is equipped with differential pressure sensing, which can implement automatic speed regulation function to ensure the long-term exhaust effect of the fan and increase the use time of the filter.

4. Optional differential pressure alarm function. When the filter reaches a certain level of blockage, the fan will start the automatic alarm function to prompt the owner to replace the filter and ensure the ventilation volume of the exhaust air.

5. The effect of intelligent sterilization lamp can be configured first, and the sterilization lamp can be set to start or close in advance, so that the exhaust fan can be started in advance, and the residual bacteria can be disinfection and sterilization in advance when the fan stays. The Ting Shi shutdown function can effectively disinfect the bacteria and cold water accumulated in the filtered air after ventilation. Reduce bacterial growth in the filter.

(1) Adopting self-developed sixth generation impellers to achieve drag reduction and noise reduction technology, which is in line with the optimal tooth profile combination for this type of fan. The number of teeth, tooth height, tooth width, and the gradual combination of teeth are key factors affecting the efficiency and noise of the fan. The acoustic comparison test results reveal that biomimetic serrations are beneficial in preventing the formation of shedding vortices on the blade surface due to turbulent boundary layer, and have a certain effect on noise reduction and sound quality improvement of the fan. Effectively reduces high-frequency eddy current noise, achieves high-precision balance of the impeller, and can control the overall vibration value between G1.0-G2.0 according to international standard G2.5.

(2) Motor brand: When the fan is used for conventional civil or industrial ventilation, different well-known motor brands can be selected according to customer requirements.

(3) Maintenance door: The fan is equipped with a large-sized maintenance door that can be freely removed as a whole. The maintenance door must be fastened on the inside of the box, and the insulation material must be used to seal between the maintenance door and the box frame. The maintenance door must be equipped with a high-strength fire-resistant handle, and the fixing method of the maintenance door is lock locking (cannot be fixed with bolts or self tapping screws). The lock locking foot must be matched on the aluminum alloy profile frame and locked with bolts. Each maintenance door must be equipped with more than 4 sets of locks, and the outer packaging material of the lock on the maintenance door must be fire-resistant engineering plastic.

(4) Wind outlet flange: Both the inlet and outlet are equipped with connecting flanges, which are made of aluminum alloy or galvanized sheet material to facilitate soft connection with the air duct and ensure a long service life in humid environments. (5) The snail shell free fan is equipped with a direct connected motor, which eliminates belt debris generated by belt transmission and is particularly suitable for clean systems.

(6) The fan is equipped with a 6P outdoor waterproof terminal junction box, which is convenient for customers to install and wire, suitable for various environments and outdoor use.

(7) Stainless steel observation window, made of 5MM thick tempered glass, achieves high strength compression performance and can withstand more than 200 degrees of high temperature. The observation window is placed at the position of the impeller, which is convenient for customers to debug the positive and negative rotation of the fan after installation and wiring, and the use of the impeller!

(8) Accurate computer selection ensures precise matching.

(1) Adopting internationally renowned brand motors and frequency converters, with high efficiency, low vibration, good heat dissipation, stable and reliable performance.

(2) Non electromagnetic frequency converters can be used to prevent high-frequency electromagnetic noise from the motor in spaces with special requirements for high silence.

(3) The snail shell free fan is equipped with a direct connected motor, which does not require belt transmission, has high efficiency, low noise, and no belt debris pollution problem.

(4) The frequency converter can be installed separately in the unit casing for convenient daily operation, and a motor with a built-in frequency converter can also be optionally selected.

(1) We use air filtration products from well-known domestic and foreign brands.

(2) Using CFD simulation technology, optimize the installation structure of the filter to ensure optimal filtration effect.

(3) All specifications of filters can choose antibacterial products containing high-efficiency antibacterial agents.

● Plate type initial efficiency filter

The filter material is a synthetic fiber woven from imported polyamide monofilament fibers, designed with multiple pleats, with a filtration efficiency of G3~G4 and an initial resistance of less than 70Pa; Adopting high-strength and moisture resistant paper frame, the structure is lightweight, the price is affordable, and the maintenance cost is low; Suitable for one-time disposal and meets the environmental requirements of clean operating room construction standards.

● Bag type medium efficiency filter

Adopting new composite non-woven fabric or imported synthetic fiber filter media, the filtration efficiency can be selected from F5 to F8; Large filtration area, low frontal wind speed, large dust holding capacity, initial resistance less than 150Pa; Adopting ultrasonic welding technology, it has good airtightness and stable performance; Equipped with various metal frames such as galvanized sheet and aluminum alloy, it has high structural strength, long service life, and can be repeatedly cleaned and used.

● Dense pleated sub high efficiency filter

The filtering material is glass fiber filter paper or ultrafine polypropylene filter paper, and the filtering efficiency can be selected from H9~H13. The filtering area is large, the resistance is small, and the initial resistance is less than 400Pa; The outer frame is made of high-strength environmentally friendly plastic and sealed with a new type of polyurethane sealant; The overall environmental protection is incineratable, non-toxic and odorless, easy to dispose of, and meets the environmental requirements of clean operating room construction standards.

|  |  |  |  |

Silencers can be divided into inlet and outlet silencers. They can be equipped with impedance composite silencers or metal microporous plate silencers, which can be configured according to different noise requirements.

PLC (Programmable Logic Controller) can be used to achieve fully automatic control, with high reliability, convenient use, powerful functions, easy maintenance, and easy expansion of external connections. It can reserve interfaces and communication protocols to connect with BAS (Building Automation System) for remote control. The operation display of the unit configuration adopts full Chinese display, which is simple and easy to use. PLC can achieve on/off control of the unit, interlock control of the fan, various protective measures (such as fan motor overload, insufficient air, filter blockage, etc.) and fault alarms, PID control, and timed on/off control. The operating parameters of the unit can be modified on-site, and triple password protection is configured to prevent misoperation and malicious operation, ensuring security.

(1) The sterilization section can be equipped with ultraviolet lamps (UV), ozone generators (0 *), activated carbon filters, nano photocatalysts (TiO.+UV), and enzyme sterilization accessories to effectively kill bacteria in the circulating air.

(2) UV sterilization lamps can be used before the filter, which can effectively kill bacteria in the circulating air and on the filter. At the same time, they are linked with the fan and equipped with electronic switches or limit switches on the unit door panel, which can effectively prevent UV light from harming operators.

(3) Customers can also choose sterilization and disinfection accessories such as ozone generators, electronic filters, activated carbon filters, nano photocatalysts, and biological enzyme sterilization according to their needs.

| (1) Primary filter, divided into plate type and bag type, plate type primary filter adopts multi-layer aluminum alloy wire mesh or chemical fiber material; The initial effect of the bag is made of non-woven fabric or special synthetic fiber, which has the advantages of water resistance, low resistance, and stable performance. The initial filtration level can reach G4. (2) Medium efficiency filter, divided into plate and bag types, using ultra-fine chemical fiber or glass fiber filter material, with the characteristics of long service life and stable performance. The medium efficiency filtration level can reach F8. (3) High efficiency and sub high efficiency filters use ultra-fine synthetic fiber or glass fiber filter materials, with dense pleated and bag type options available. The high and sub high efficiency filtration levels can reach H13. (4) Chemical filters and photocatalysts mainly remove chemical pollutants from the air. There are activated carbon cylinders available for selection. |

| According to different usage requirements and the characteristics of fan noise, the sound-absorbing section can use microporous plate mufflers or perforated plates with built-in sound-absorbing cotton. When air passes through perforated panels with built-in sound-absorbing cotton, it has a good sound-absorbing effect on medium and high-frequency noise. The interior of the microporous plate muffler is a cavity, and the frame is made of perforated galvanized steel plate, lined with ultra-fine glass wool and wrapped with glass fiber cloth. It uses the principle of resonance sound absorption in physics to absorb sound waves, and has the advantages of non pollution and moisture resistance. It has an effective sound-absorbing effect on low-frequency and mid frequency noise. The silencing section is divided into return air silencing and supply air silencing. |

(1) The unit adopts a dual inlet centrifugal fan, which has three forms: forward leaning, backward leaning, and wing shaped.

(2) The fan impeller is dynamically and statically balanced according to the air volume and speed.

(3) The fan and motor are assembled on the same frame, and shock absorbers are used for isolation.

(4) The motor adopts a three-phase asynchronous motor with good insulation properties.

(5) The fan section has maintenance doors and power holes, which facilitate user maintenance and power connection.

(6) Variable speed motors can be selected according to customer requirements.

(7) The motor can be selected with other voltages and frequencies according to customer requirements.

(8) The air supply methods of the fan section are divided into

(1) The technical parameters listed in the sample are all standard units, which can be designed according to the actual requirements of the project in practical engineering. When customers place orders, they should provide the design parameters of the equipment, such as air volume, unit total pressure, inlet and outlet air parameters, cleanliness requirements, etc.

(2) If the customer needs a more detailed understanding of the fan parameters, please notify our company to provide the characteristic curve of the fan separately.

(3) Our company can adjust the form and size of the air outlet according to actual requirements.

(4) Due to the flexible combination of various functional segments, if customers need detailed information on the total weight of the machine, please notify our company to provide the weight of the unit separately.

(5) Please feel free to contact Horsepower Company for any other specific requirements in actual engineering.

On site installation should be carried out under the guidance of professional technicians who are familiar with and trained on this product. During installation, the following points should be noted:

(1) Before installation, please check whether the model and quantity of each accessory on the packing list are correct.

(2) A set of assembly drawings is randomly attached to the unit, and installation should strictly follow the drawings provided by the horsepower company.

(3) During the installation of the unit, debris inside the unit should be promptly removed,

(4) When installing the unit, there should be space available for each functional section to function.

(5) Check the lubrication condition of each rotating component and whether each adjusting device is flexible.

(6) The unit shall not bear the weight of external pipelines and air ducts.

(7) Flexible connections should be used between the dedicated air purification fan box and the external air duct to avoid the transmission of vibration.

(8) The connections between unit sections and between box boards must be tight.

(9) If there is a sealing rubber strip, it must be tightly pressed to prevent air leakage.

(10) The air filter should be installed after other components of the unit have been installed, and the filter material of the air filter should be checked for damage or contamination before installation.

The installation of pipeline systems should comply with local regulations. Pipelines should be designed to minimize bending and vertical displacement as much as possible to save costs and maintain optimal unit performance. The pipeline must be insulated.

The correct installation should include the following points:

(1) Pipelines should be equipped with shock absorbers. Reduce vibration and prevent pipeline loosening and air leakage.

(2) Maintenance valves should be installed on pipelines. It can be opened and closed during maintenance to isolate the unit from the pipeline system.

(3) The pipeline system should be equipped with air volume control valves, static pressure boxes, etc., and silencers should be installed in environments with specific requirements for low noise.

(4) If the fan is installed in a mezzanine, sufficient maintenance space and access ports must be reserved.

(5) The dedicated air purification fan box and external air duct should not have bends, diameter changes, or misalignment installation within a distance of twice the impeller diameter of the fan.

Product Category: Purification Fan