Related product categories

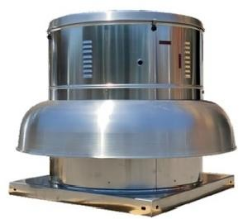

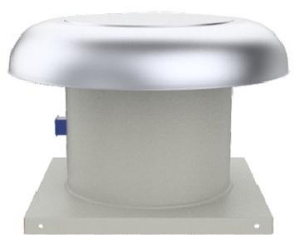

RF-L type all aluminum centrifugal roof fan

|  |

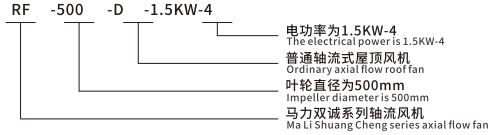

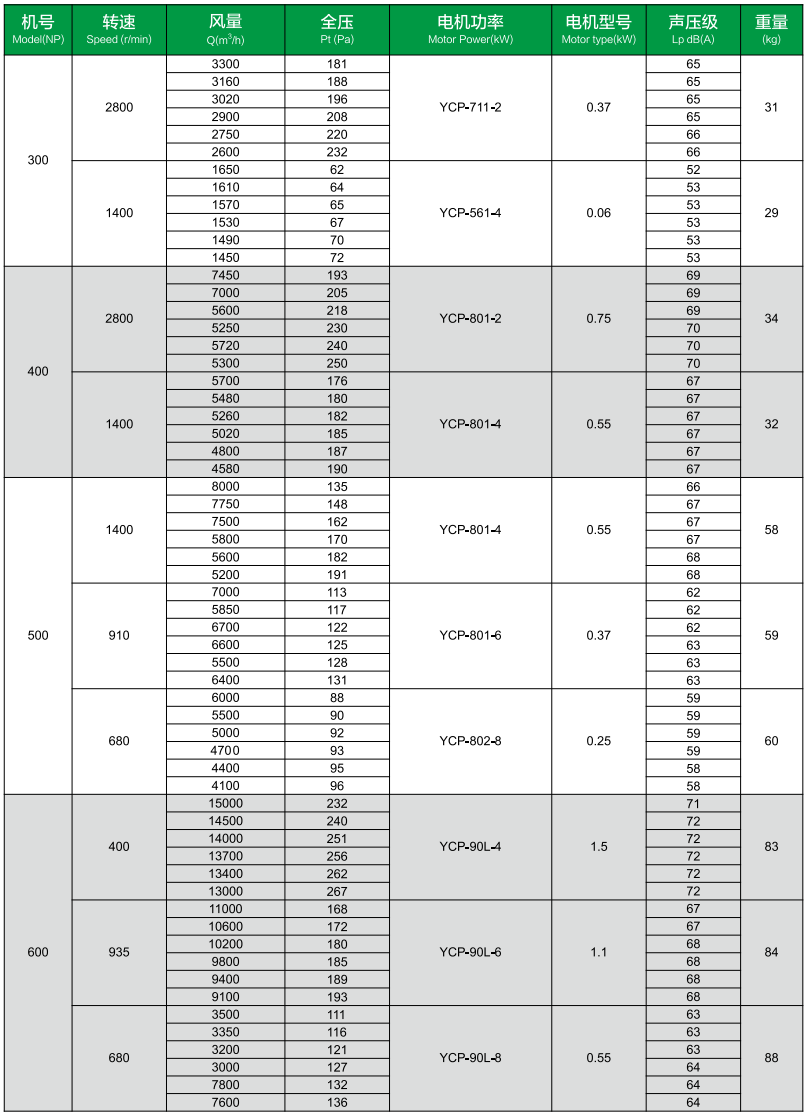

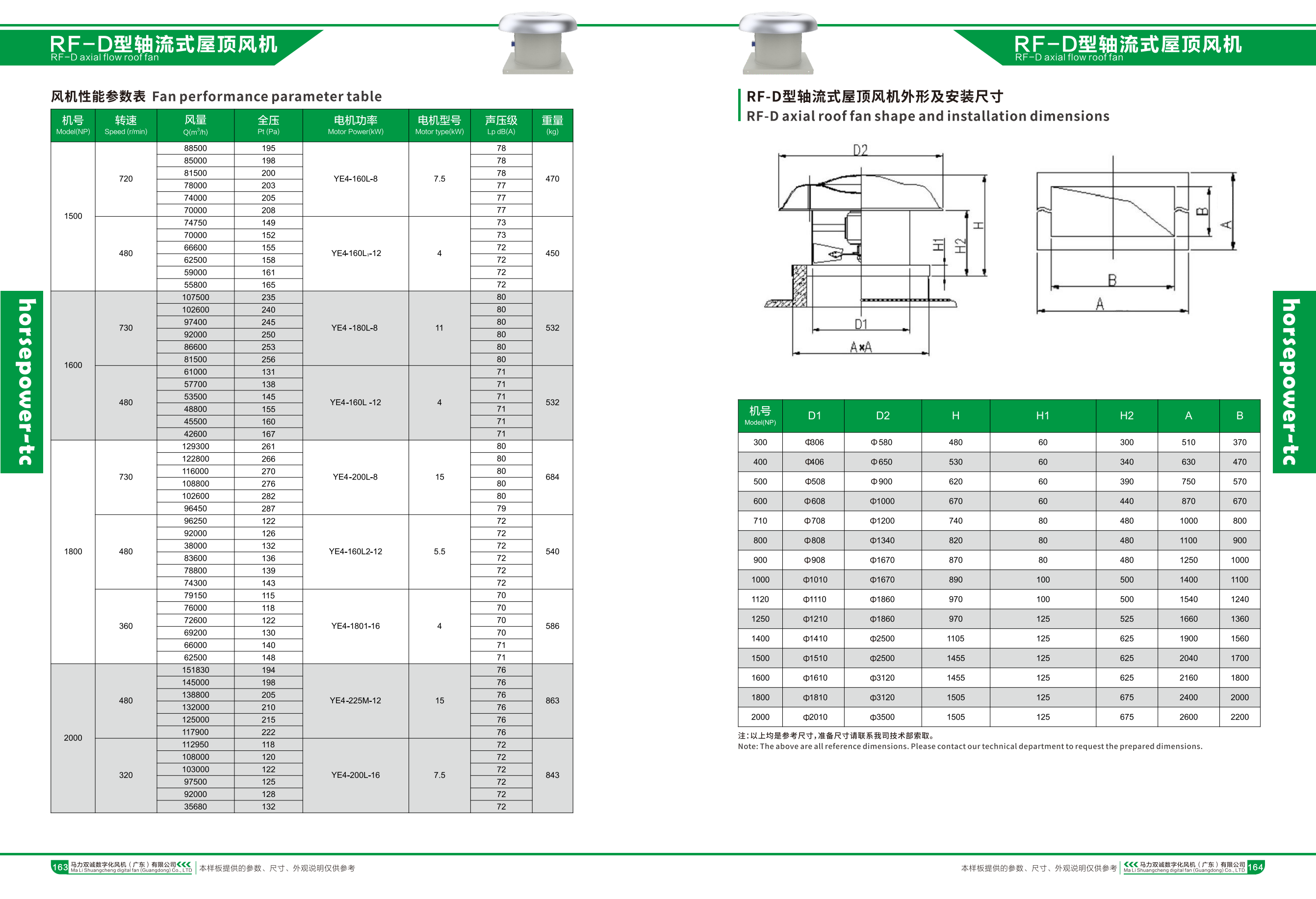

1.1 RF-D type axial flow roof fan, with the same blade design principle as RF type axial flow fan, adopts a wide blade, large chord length space twisted and inclined blade shape, which can achieve the required air volume and pressure at low speed operation, thereby reducing fan noise.

1.2. The fan is divided into 17 specifications according to the impeller diameter of 300-2400mm, with an air volume of 1500~200000m ³/h and a total pressure of 60~320Pa. The blades of the fan with a machine number greater than or equal to 12 # can be made with adjustable blade angles to meet different working conditions and achieve energy saving and noise reduction. According to the speed regulation method, it can be divided into single speed, dual speed, and variable frequency (the fan motor adopts a variable frequency motor, equipped with a variable frequency controller, and implements variable frequency speed regulation to meet the needs of different working conditions. It is recommended to adjust the frequency to be locked at 25Hz~50Hz). To meet the requirements of explosion-proof environment, the fan can be made into an explosion-proof fan with an explosion-proof rating of EXdIIBT4.

1.3. The fan can be equipped with manual or electric regulating valves, self hanging louvers, etc. according to user needs.

Conventional type: non corrosive, non flammable, explosive gas (with a dust content not exceeding 100mg/m ³);

Explosion proof type: non corrosive containing flammable and explosive gases (with a dust content not exceeding 100mg/m ³);

Anti corrosion type: It contains corrosive gases (without any dust).

Fans can be widely used for medium and low pressure, high flow ventilation and air exchange in high-rise buildings, industrial and mining enterprises, power stations, stations, sports venues, and other areas.

4.1 Standard configuration: impeller, casing (air duct, motor bracket), motor, foot, fiberglass wind cap, safety net

4.2 Optional parts and accessories (indicate whether purchased when ordering): self hanging louvers, control box, bird proof net

5.1 Fan impeller: The cross of the fixed angle roof fan impeller is made of steel stamped and formed by hydraulic pressure. The blades are made of aluminum alloy stamped and formed by hydraulic pressure. The blades are riveted and assembled with the cross; The cross shaped impeller of the variable angle roof fan is made of aluminum die-casting, and the blades are made of aluminum alloy stamped and hydraulically formed. The impeller has undergone static and dynamic balance correction, and the balance accuracy is not greater than G5.6 level.

5.2. The casing of the steel roof fan is made by integral spinning and flanging, while the casing of the fiberglass roof fan is made of fiberglass and the fan cap is made of fiberglass and formed in one go.

|  |

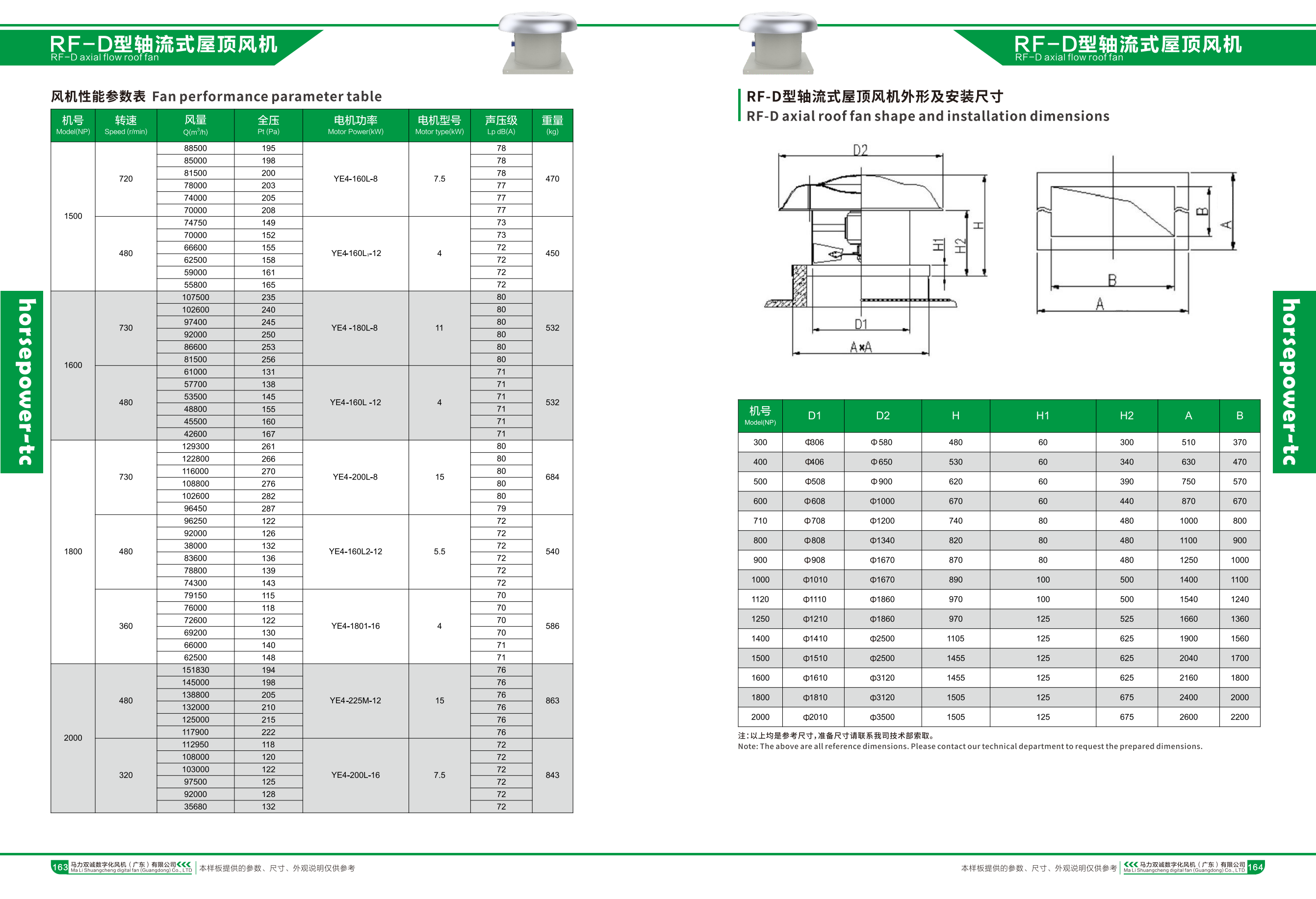

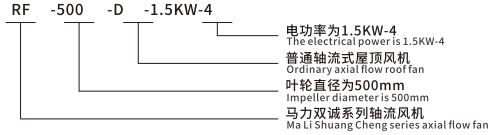

1.1 RF-D type axial flow roof fan, with the same blade design principle as RF type axial flow fan, adopts a wide blade, large chord length space twisted and inclined blade shape, which can achieve the required air volume and pressure at low speed operation, thereby reducing fan noise.

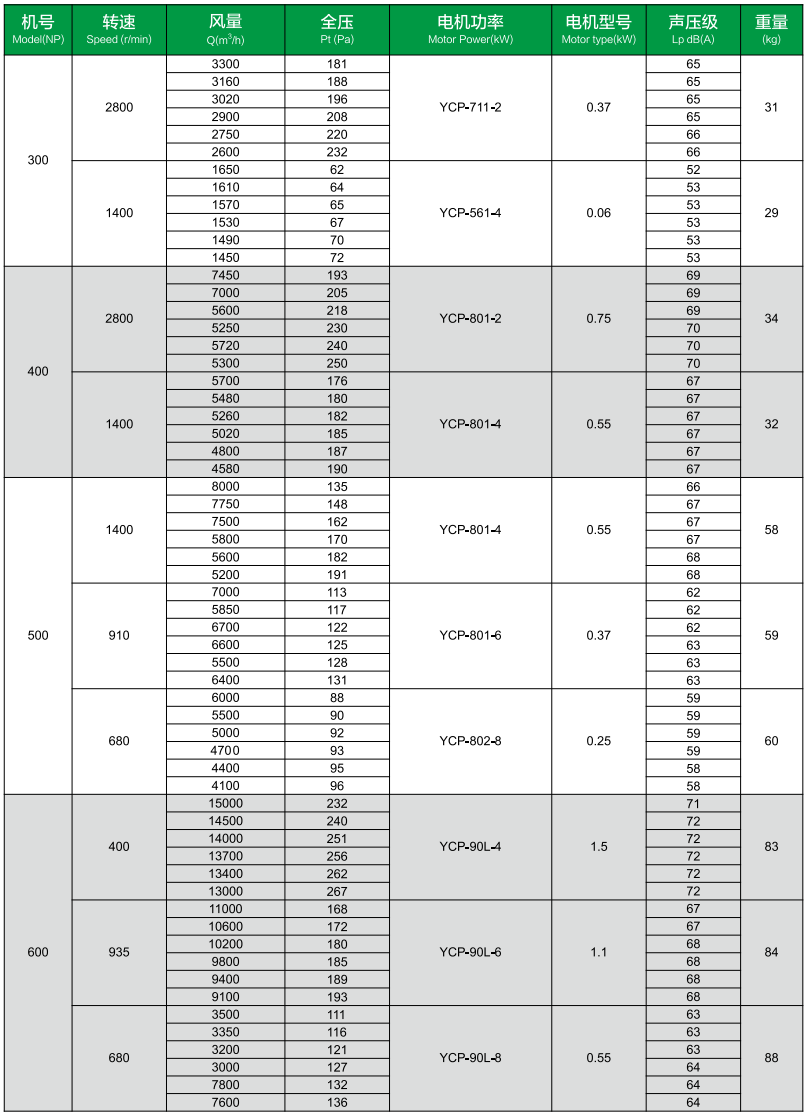

1.2. The fan is divided into 17 specifications according to the impeller diameter of 300-2400mm, with an air volume of 1500~200000m ³/h and a total pressure of 60~320Pa. The blades of the fan with a machine number greater than or equal to 12 # can be made with adjustable blade angles to meet different working conditions and achieve energy saving and noise reduction. According to the speed regulation method, it can be divided into single speed, dual speed, and variable frequency (the fan motor adopts a variable frequency motor, equipped with a variable frequency controller, and implements variable frequency speed regulation to meet the needs of different working conditions. It is recommended to adjust the frequency to be locked at 25Hz~50Hz). To meet the requirements of explosion-proof environment, the fan can be made into an explosion-proof fan with an explosion-proof rating of EXdIIBT4.

1.3. The fan can be equipped with manual or electric regulating valves, self hanging louvers, etc. according to user needs.

Conventional type: non corrosive, non flammable, explosive gas (with a dust content not exceeding 100mg/m ³);

Explosion proof type: non corrosive containing flammable and explosive gases (with a dust content not exceeding 100mg/m ³);

Anti corrosion type: It contains corrosive gases (without any dust).

Fans can be widely used for medium and low pressure, high flow ventilation and air exchange in high-rise buildings, industrial and mining enterprises, power stations, stations, sports venues, and other areas.

4.1 Standard configuration: impeller, casing (air duct, motor bracket), motor, foot, fiberglass wind cap, safety net

4.2 Optional parts and accessories (indicate whether purchased when ordering): self hanging louvers, control box, bird proof net

5.1 Fan impeller: The cross of the fixed angle roof fan impeller is made of steel stamped and formed by hydraulic pressure. The blades are made of aluminum alloy stamped and formed by hydraulic pressure. The blades are riveted and assembled with the cross; The cross shaped impeller of the variable angle roof fan is made of aluminum die-casting, and the blades are made of aluminum alloy stamped and hydraulically formed. The impeller has undergone static and dynamic balance correction, and the balance accuracy is not greater than G5.6 level.

5.2. The casing of the steel roof fan is made by integral spinning and flanging, while the casing of the fiberglass roof fan is made of fiberglass and the fan cap is made of fiberglass and formed in one go.

Product category: Roof fan