Related product categories

|  |

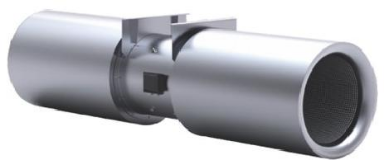

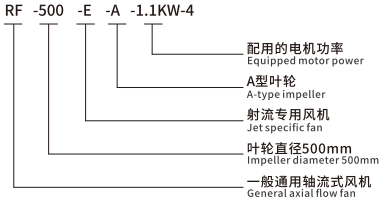

Jet fans are mainly used in longitudinal ventilation systems of highway and railway tunnels. The fans are generally suspended at the top or on both sides of the tunnel, do not occupy traffic area, and do not require additional construction of air ducts. Soil

Low construction cost is a very economical ventilation method.

When the fan is working, it can generate high thrust from the given energy. At this point, a portion of the total air flow passing through the tunnel is sucked in by the fan, and after the impeller performs work, it is ejected at high speed from the outlet.

Based on the principle of impact transmission, high-speed airflow will transfer energy to the air inside the tunnel, pushing the air inside the tunnel to flow forward together. When the flow velocity decays to a certain value, the next set of winds

The machine continues to work. In this way, fresh air is drawn in from the entrance of the tunnel and polluted air is discharged from the exit.

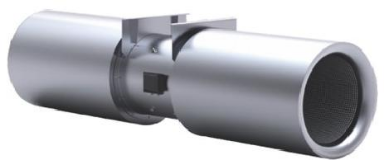

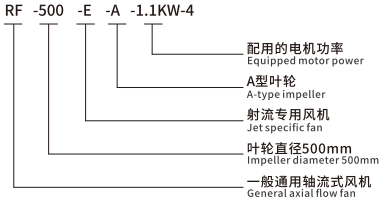

Our company has accumulated years of experience in designing and producing tunnel ventilation equipment. Based on the RF-E jet fan, in order to better match the ventilation requirements of tunnels with the jet fan, we have also developed a new one

Designed 7 machine numbers and made improvements to the original machine numbers. Our RF-E jet fan has the following characteristics:

1. Wide performance range, with greater choice

2. Low energy consumption and high thrust.

3. The specially designed muffler effectively controls the noise of the fan.

4. A precisely balanced impeller ensures smooth operation of the fan.

5. A dedicated electric motor enables the fan to operate reliably for 20000 hours over a long period of time.

6. For bidirectional ventilation type, with equal forward and reverse wind speeds, simply change the direction of the motor to achieve reverse airflow.

7. Equipped with a dual speed motor, low-speed operation can reduce operating costs when there is strong natural ventilation.

8. Easy to maintain.

9. Painting process, the appearance of the fan is beautiful and generous.

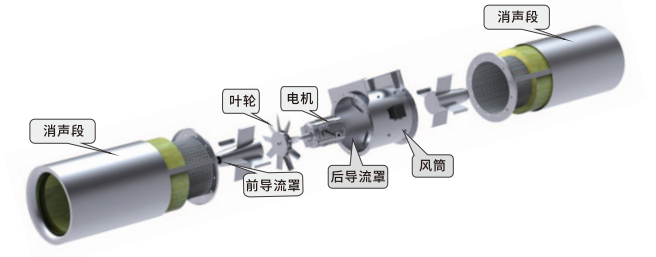

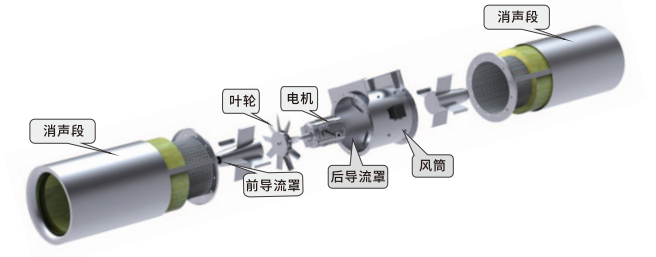

The RF-E series jet fan generally includes: muffler, diffuser, impeller, electric motor, air duct, and installation foot (as shown in the following figure)

Silencer: Silencers are installed at both ends of the fan section. The muffler is a two-layer cylindrical structure, with the inner cylinder being a perforated plate and the outer cylinder being rolled and welded from steel plates. The special ultra-fine glass wool sound-absorbing material is filled in the middle, and the streamlined nozzle improves the flow field, making the fan have high operating efficiency.

Fan impeller: The impeller is composed of a hub and different numbers of blades, connected with high-strength bolts to prevent loosening. The hub and blades are both made of high-quality high-strength ZL114A aluminum alloy by die-casting, and have undergone X-ray inspection, aging treatment, tensile testing, and metal processing, as well as static and dynamic balance verification. If you want to adjust the angle of the fan blades, you can use a tension wrench to loosen the connecting bolts between the blades and the hub, use a special angle gauge to adjust the required angle according to the curve chart provided by our company's sample, and then fix the blades in reverse order. Adjust all blades completely.

● Wind duct: The wind duct is made of high-quality steel plate with CNC plasma cutting, CNC automatic welding, and spinning forming. The outer surface is coated to ensure the strength and corrosion resistance of the fan.

Front and rear deflectors: Approximately streamlined rectifiers improve the flow field and enhance the operational efficiency of the fan.

● Electric motor: Specially designed electric motors use sealed grease lubrication, and are air-cooled squirrel cage fully enclosed wet heat products with insulation level not lower than F and protection level not lower than

IP55, the motor bearings are NSK or SKF imported bearings, which can operate normally for more than 20000 hours. The motor lead out cable can be connected to the junction box on the fan duct for easy wiring by users. Electric motors with lubricating oil nozzles can also be connected to fan ducts according to user requirements. The electric motor and fan impeller are directly driven and exposed to the air. The electric motor can also be customized according to user requirements

Equipped with bearing temperature sensors, stator winding temperature sensors, vibration alarm devices, etc.

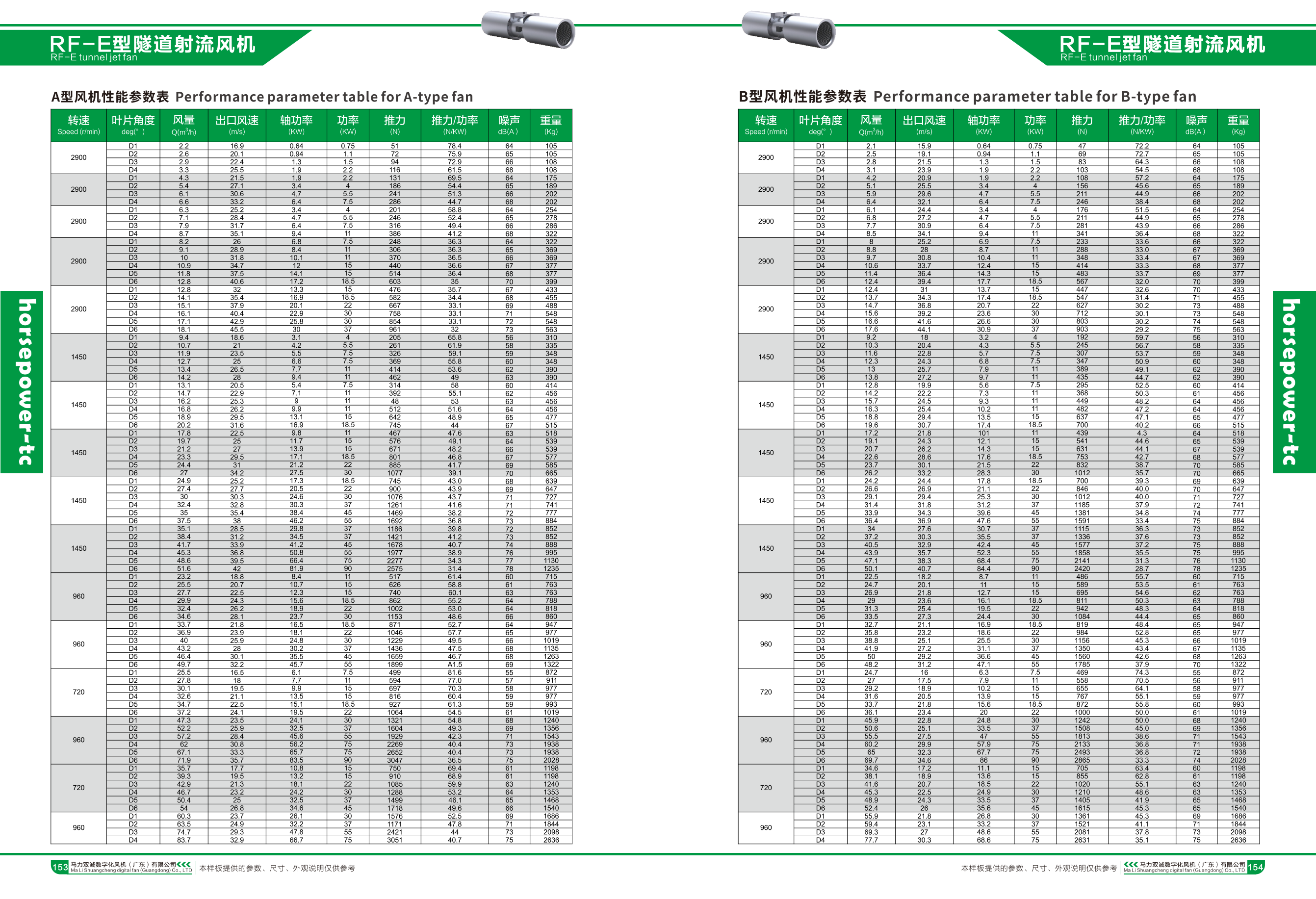

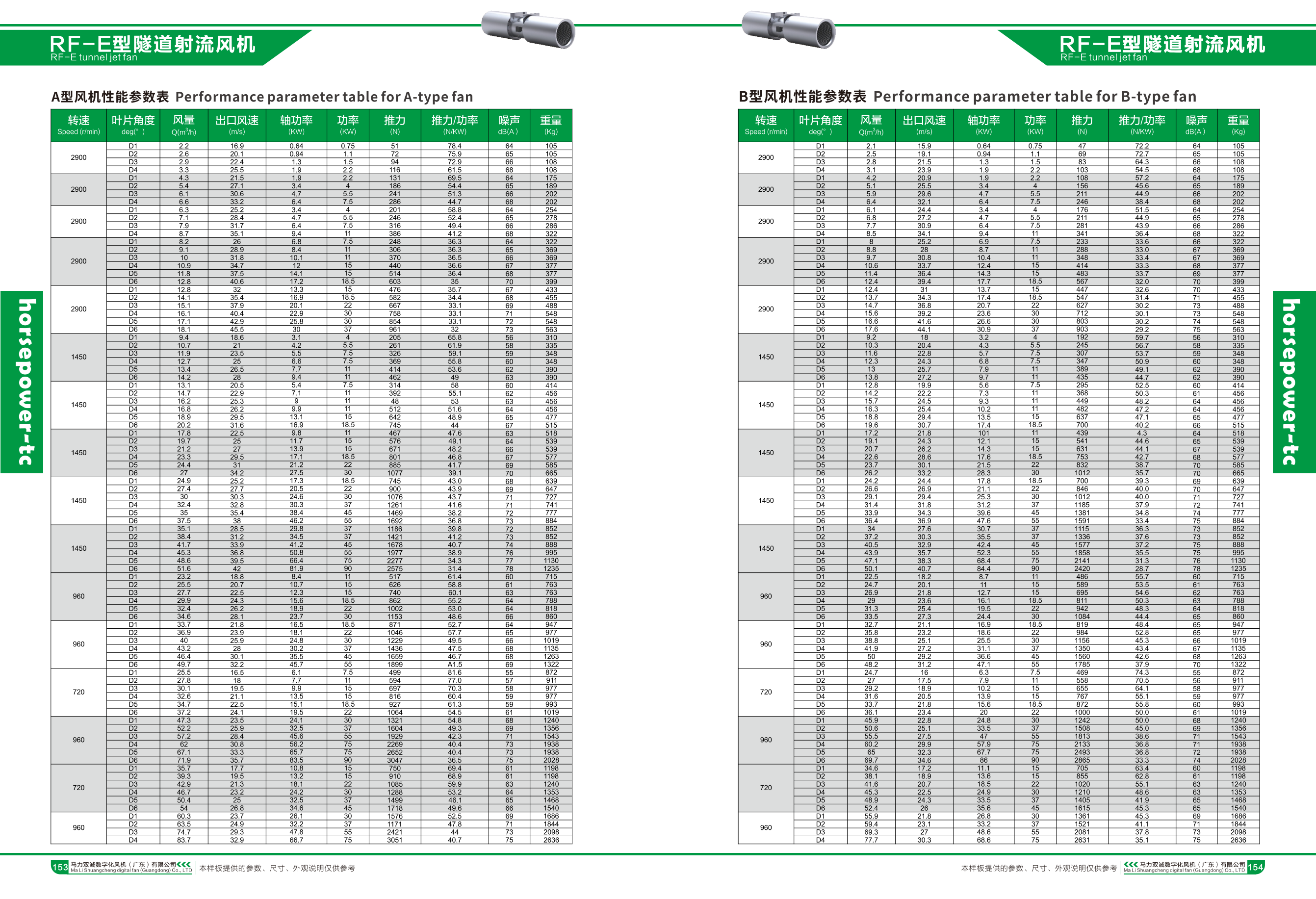

Technical data of RF-E series jet fan

(1) The data in this chapter is reliable and published based on years of practical experience and working procedures in the field of aerodynamics.

(2) The reverse air volume of K-type jet fan is 0.5-0.7 times that of positive air volume, while the reverse air volume of T-type jet fan is equal to that of positive air volume.

(3) The RDF series jet fan can operate reliably for a long time in an ambient temperature range of -25~+50 ℃. It can run continuously and reliably for 60 minutes at a high temperature of 280 ℃. Jet fans that have undergone high-temperature operation should be overhauled or replaced.

(4) All parts have undergone anti-corrosion pretreatment, coated with two layers of anti rust primer and one layer of topcoat. But for special cases, stainless steel, electroplated parts, etc. can be used.

(5) Switching time for forward and reverse rotation: The fan starts within 14 seconds, and the switching time for forward and reverse rotation is 30-60 seconds.

(6) The noise values listed in the performance parameter table are A-level measured in the field, 10 meters away from the fan outlet, at a 45 degree angle.

The installation quality of jet fans is particularly important, and embedded parts should be strictly buried according to requirements. During installation, the fan should not be bumped or damaged, and welding should not be applied to the fan.

Install the fan, ensuring that the fan axis is parallel to the centerline of the tunnel, in addition to meeting the requirements of the tunnel boundary. Otherwise, it will increase the loss of the fan.

The operation control of jet fans is generally determined by the increase or decrease of CO concentration to start or stop one or a group, high or low speed.

When starting the jet fan, in order to reduce the impact on the power grid, each fan should be started one by one, that is, the power supply of the next fan should be connected after the previous fan reaches the rated speed. If starting directly, the interval is 120 seconds.

When reversing the direction of the jet fan, wait for the impeller to completely stop before turning on the power.

The fan does not require special maintenance work. To keep the fan clean, the outer surface of the fan can be regularly wiped according to the pollution situation.

|  |

Jet fans are mainly used in longitudinal ventilation systems of highway and railway tunnels. The fans are generally suspended at the top or on both sides of the tunnel, do not occupy traffic area, and do not require additional construction of air ducts. Soil

Low construction cost is a very economical ventilation method.

When the fan is working, it can generate high thrust from the given energy. At this point, a portion of the total air flow passing through the tunnel is sucked in by the fan, and after the impeller performs work, it is ejected at high speed from the outlet.

Based on the principle of impact transmission, high-speed airflow will transfer energy to the air inside the tunnel, pushing the air inside the tunnel to flow forward together. When the flow velocity decays to a certain value, the next set of winds

The machine continues to work. In this way, fresh air is drawn in from the entrance of the tunnel and polluted air is discharged from the exit.

Our company has accumulated years of experience in designing and producing tunnel ventilation equipment. Based on the RF-E jet fan, in order to better match the ventilation requirements of tunnels with the jet fan, we have also developed a new one

Designed 7 machine numbers and made improvements to the original machine numbers. Our RF-E jet fan has the following characteristics:

1. Wide performance range, with greater choice

2. Low energy consumption and high thrust.

3. The specially designed muffler effectively controls the noise of the fan.

4. A precisely balanced impeller ensures smooth operation of the fan.

5. A dedicated electric motor enables the fan to operate reliably for 20000 hours over a long period of time.

6. For bidirectional ventilation type, with equal forward and reverse wind speeds, simply change the direction of the motor to achieve reverse airflow.

7. Equipped with a dual speed motor, low-speed operation can reduce operating costs when there is strong natural ventilation.

8. Easy to maintain.

9. Painting process, the appearance of the fan is beautiful and generous.

The RF-E series jet fan generally includes: muffler, diffuser, impeller, electric motor, air duct, and installation foot (as shown in the following figure)

Silencer: Silencers are installed at both ends of the fan section. The muffler is a two-layer cylindrical structure, with the inner cylinder being a perforated plate and the outer cylinder being rolled and welded from steel plates. The special ultra-fine glass wool sound-absorbing material is filled in the middle, and the streamlined nozzle improves the flow field, making the fan have high operating efficiency.

Fan impeller: The impeller is composed of a hub and different numbers of blades, connected with high-strength bolts to prevent loosening. The hub and blades are both made of high-quality high-strength ZL114A aluminum alloy by die-casting, and have undergone X-ray inspection, aging treatment, tensile testing, and metal processing, as well as static and dynamic balance verification. If you want to adjust the angle of the fan blades, you can use a tension wrench to loosen the connecting bolts between the blades and the hub, use a special angle gauge to adjust the required angle according to the curve chart provided by our company's sample, and then fix the blades in reverse order. Adjust all blades completely.

● Wind duct: The wind duct is made of high-quality steel plate with CNC plasma cutting, CNC automatic welding, and spinning forming. The outer surface is coated to ensure the strength and corrosion resistance of the fan.

Front and rear deflectors: Approximately streamlined rectifiers improve the flow field and enhance the operational efficiency of the fan.

● Electric motor: Specially designed electric motors use sealed grease lubrication, and are air-cooled squirrel cage fully enclosed wet heat products with insulation level not lower than F and protection level not lower than

IP55, the motor bearings are NSK or SKF imported bearings, which can operate normally for more than 20000 hours. The motor lead out cable can be connected to the junction box on the fan duct for easy wiring by users. Electric motors with lubricating oil nozzles can also be connected to fan ducts according to user requirements. The electric motor and fan impeller are directly driven and exposed to the air. The electric motor can also be customized according to user requirements

Equipped with bearing temperature sensors, stator winding temperature sensors, vibration alarm devices, etc.

Technical data of RF-E series jet fan

(1) The data in this chapter is reliable and published based on years of practical experience and working procedures in the field of aerodynamics.

(2) The reverse air volume of K-type jet fan is 0.5-0.7 times that of positive air volume, while the reverse air volume of T-type jet fan is equal to that of positive air volume.

(3) The RDF series jet fan can operate reliably for a long time in an ambient temperature range of -25~+50 ℃. It can run continuously and reliably for 60 minutes at a high temperature of 280 ℃. Jet fans that have undergone high-temperature operation should be overhauled or replaced.

(4) All parts have undergone anti-corrosion pretreatment, coated with two layers of anti rust primer and one layer of topcoat. But for special cases, stainless steel, electroplated parts, etc. can be used.

(5) Switching time for forward and reverse rotation: The fan starts within 14 seconds, and the switching time for forward and reverse rotation is 30-60 seconds.

(6) The noise values listed in the performance parameter table are A-level measured in the field, 10 meters away from the fan outlet, at a 45 degree angle.

The installation quality of jet fans is particularly important, and embedded parts should be strictly buried according to requirements. During installation, the fan should not be bumped or damaged, and welding should not be applied to the fan.

Install the fan, ensuring that the fan axis is parallel to the centerline of the tunnel, in addition to meeting the requirements of the tunnel boundary. Otherwise, it will increase the loss of the fan.

The operation control of jet fans is generally determined by the increase or decrease of CO concentration to start or stop one or a group, high or low speed.

When starting the jet fan, in order to reduce the impact on the power grid, each fan should be started one by one, that is, the power supply of the next fan should be connected after the previous fan reaches the rated speed. If starting directly, the interval is 120 seconds.

When reversing the direction of the jet fan, wait for the impeller to completely stop before turning on the power.

The fan does not require special maintenance work. To keep the fan clean, the outer surface of the fan can be regularly wiped according to the pollution situation.

Product Category: Tunnel Jet Fan