Related product categories

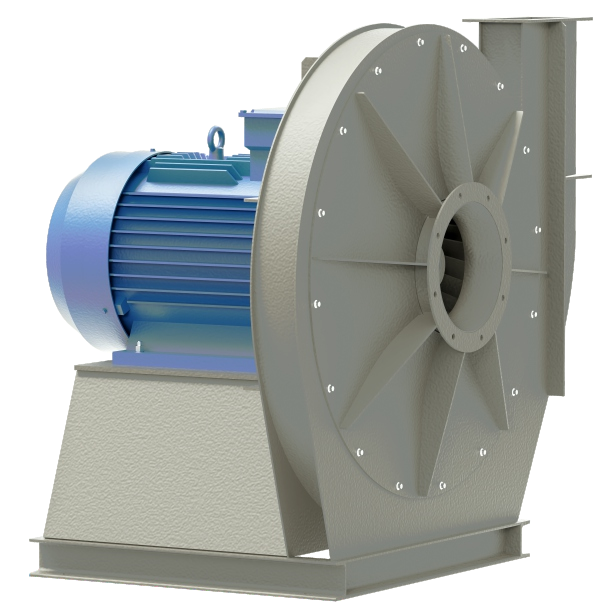

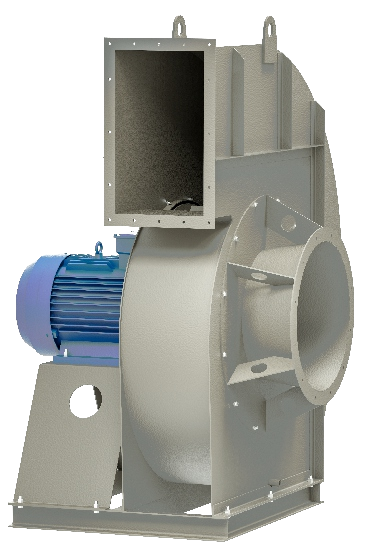

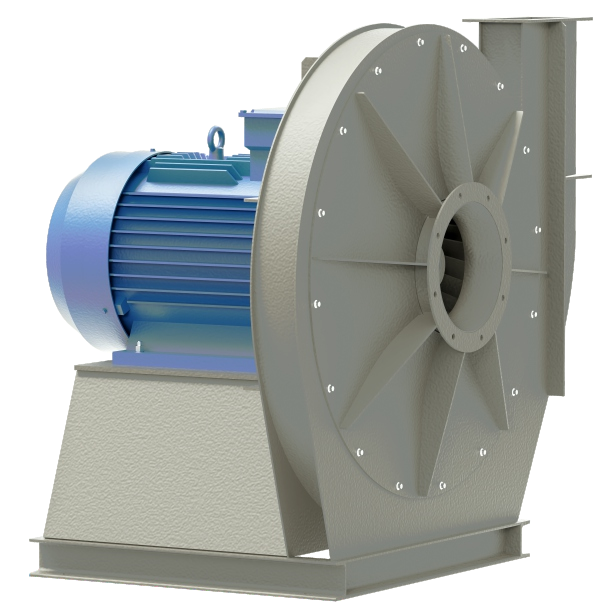

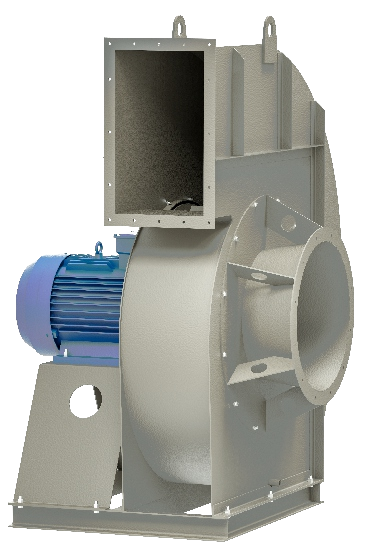

FAN10 D-type centrifugal fan

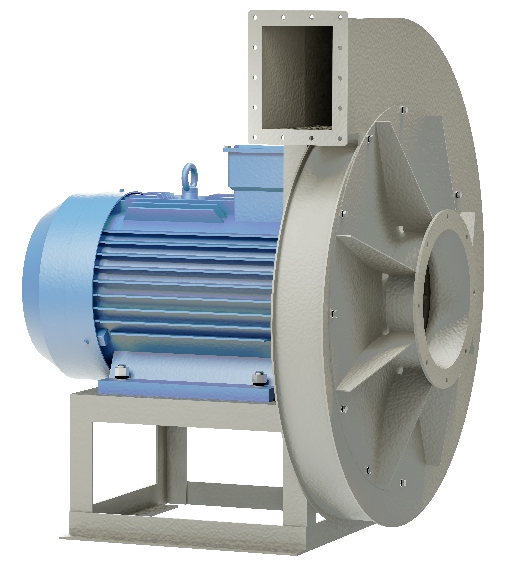

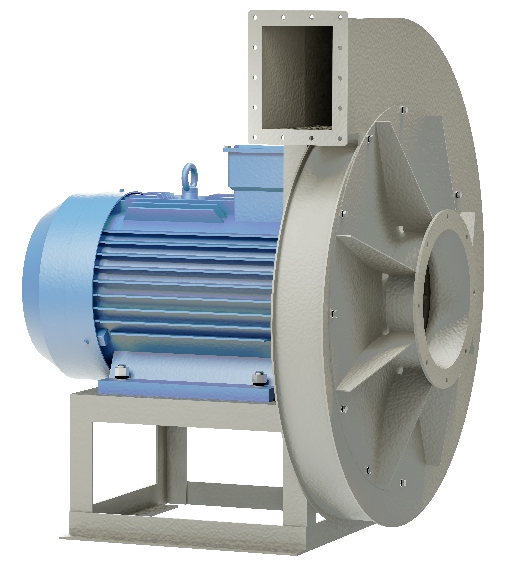

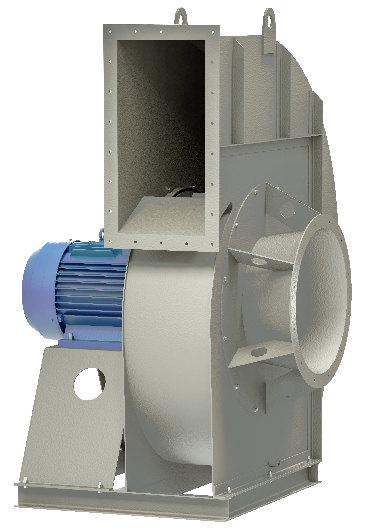

FAN15 centrifugal fan

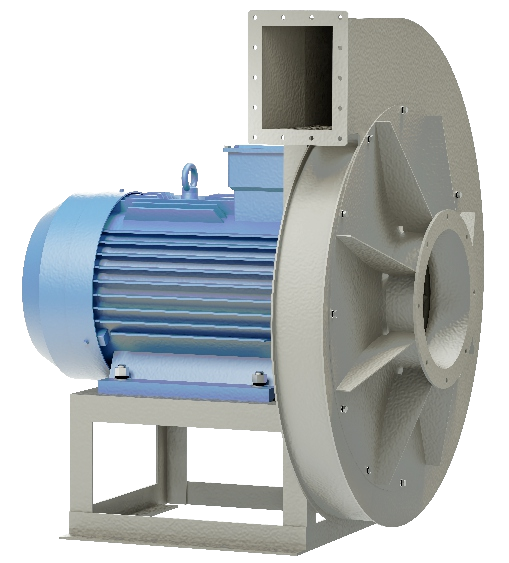

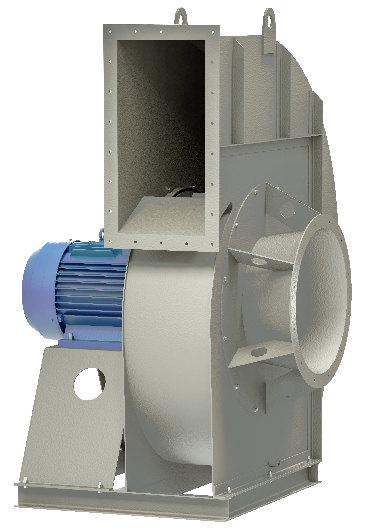

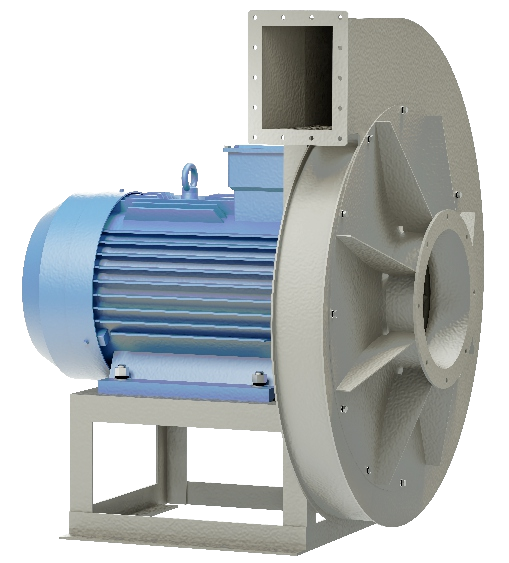

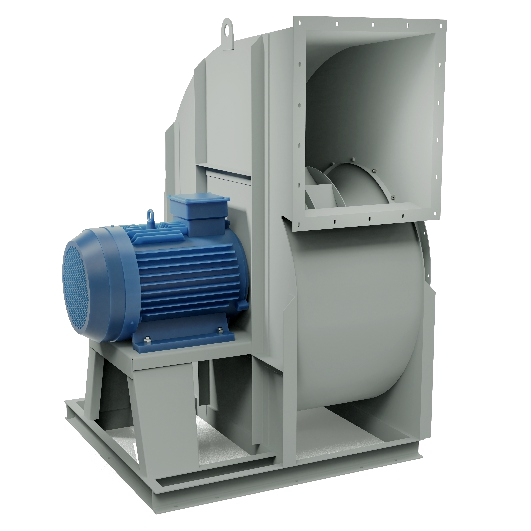

FAN20 centrifugal fan

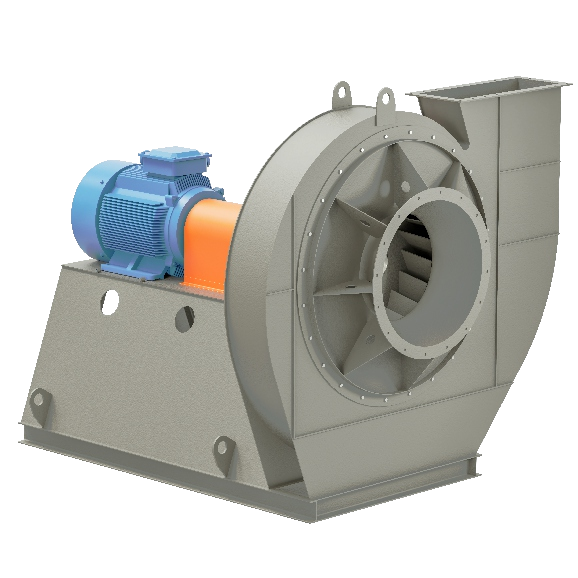

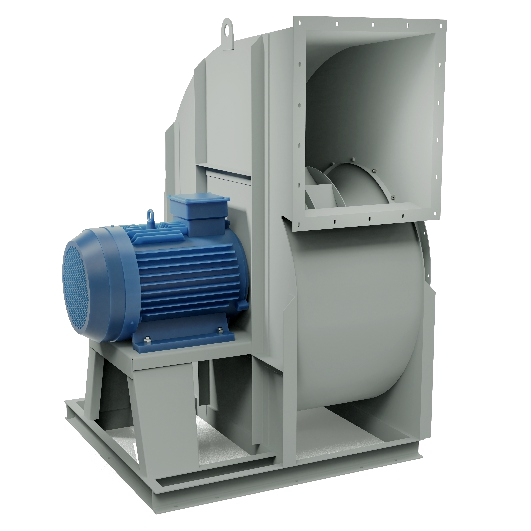

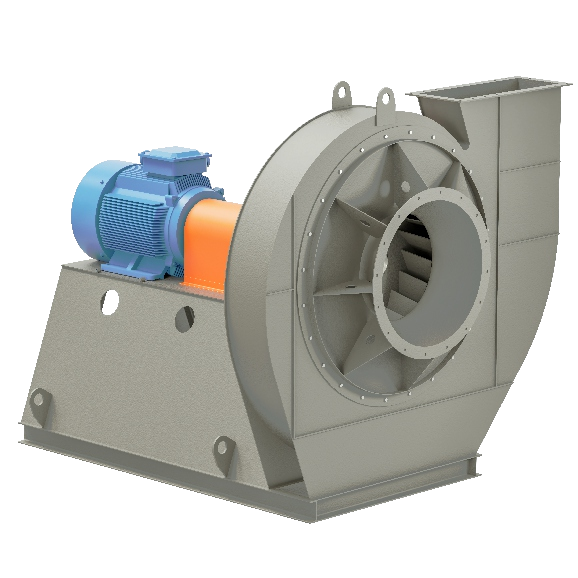

FAN21 centrifugal fan

FAN28 centrifugal fan

FAN30 centrifugal fan

FAN35 centrifugal fan

FAN55 centrifugal fan

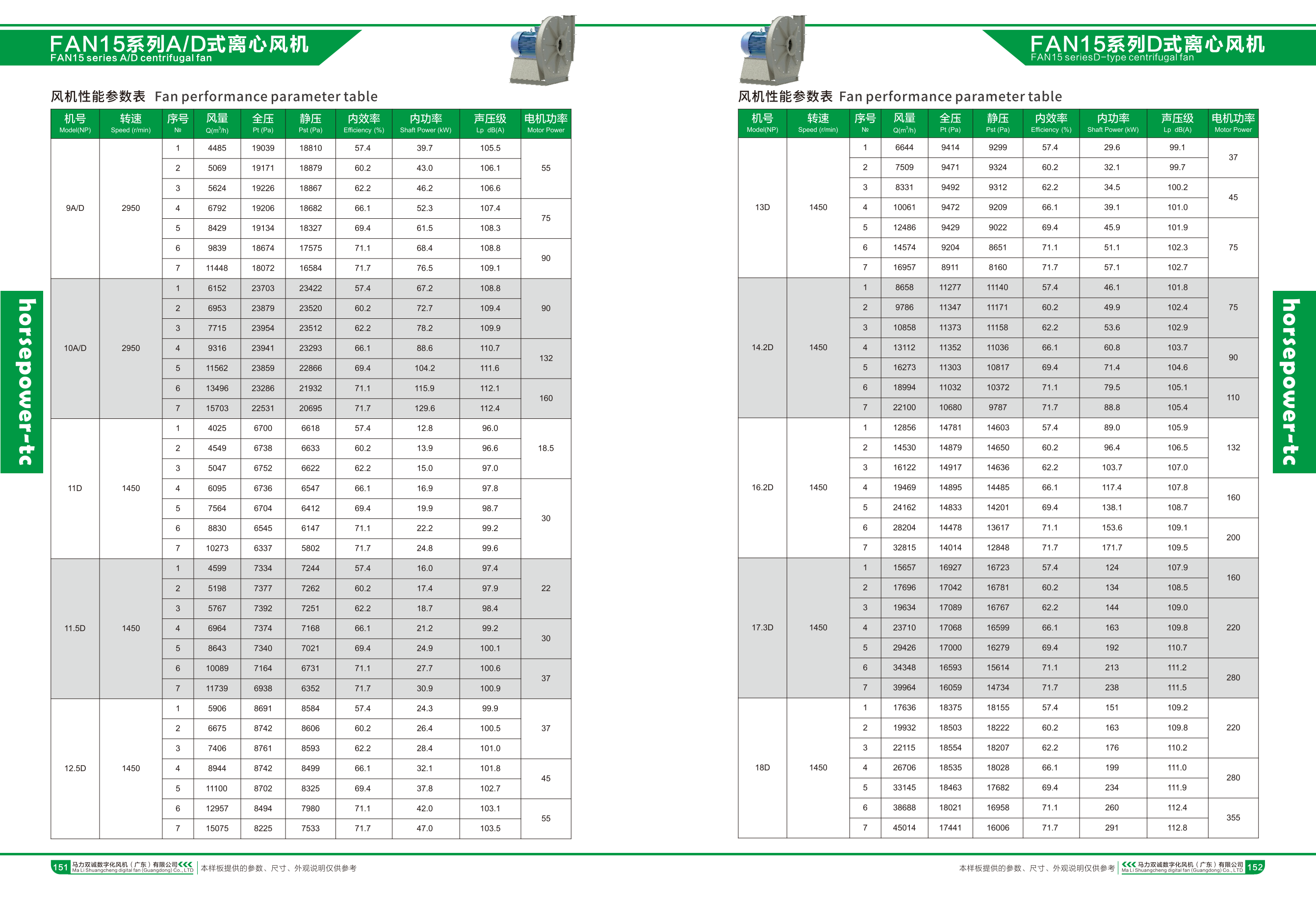

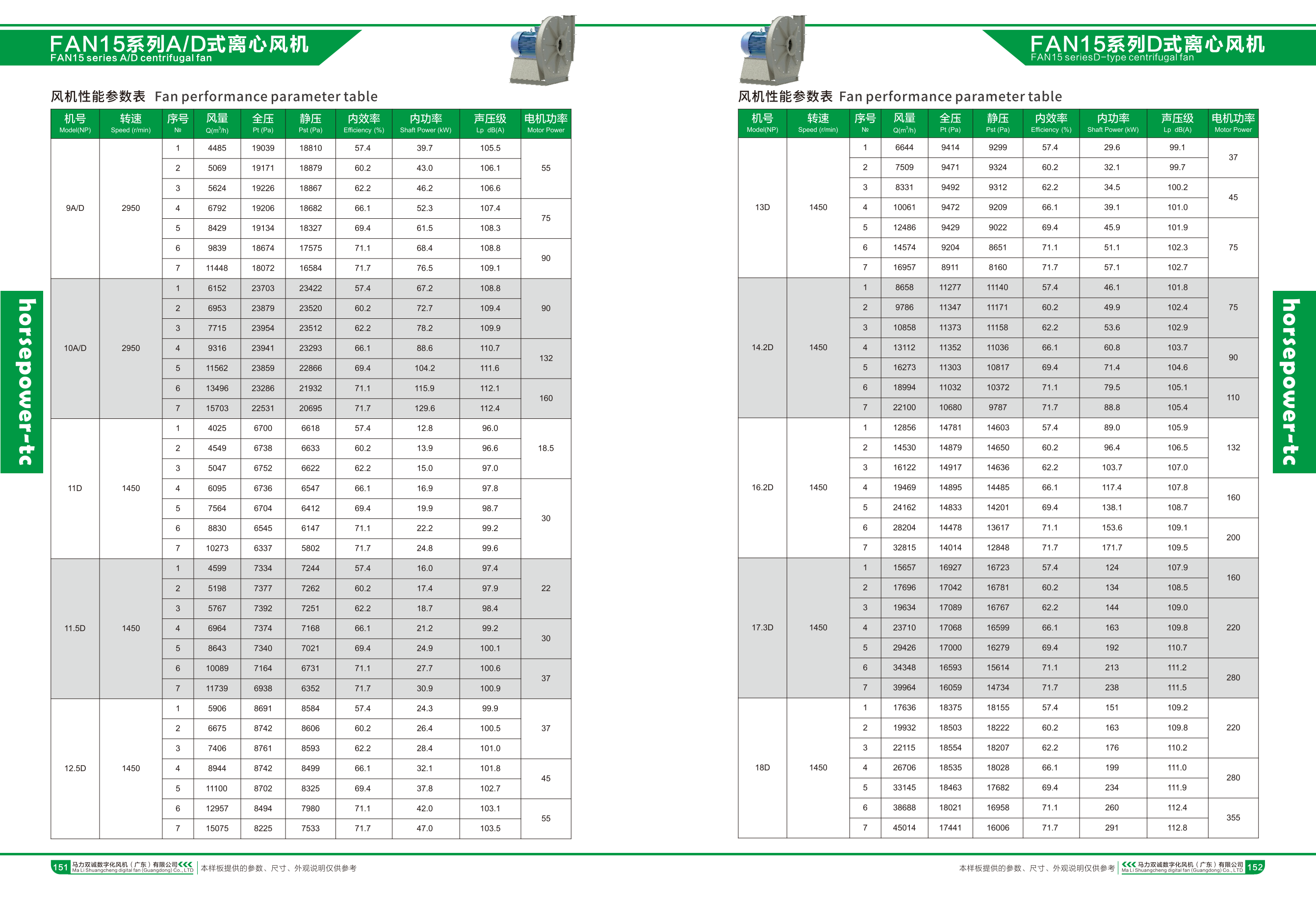

Airflow range: 130-45014m ³/h.

Full pressure range: 1543-23954pa.

The fan transmission system is structurally equipped with Type A and Type D.

The fan specifications range from 2.8 to 17, with a total of 20 machine numbers.

The fan outlet can be made into seven standard angles: 0 °, 45 °, 90 °, 135 °, 180 °, 225 °, and 270 °. FAN15-G high-temperature centrifugal fan is suitable for baking ovens, drying ovens, and high-temperature gas circulation at temperatures not exceeding 280C. FAN15-G high-temperature centrifugal fan: A type fan is equipped with a special motor and a heat dissipation impeller, while C (D) type fan is equipped with a heat dissipation impeller. The basic installation dimensions are the same as FAN15, and special customization is required for temperatures exceeding 280C.

Fan structure:

Impeller group:

The impeller adopts rear curved R blades welded from steel plates, which have the advantages of high efficiency, high pressure, and low noise. Add reinforcing ribs at high speeds to increase rigidity. The dynamic balance accuracy of the impeller is ≤ 5.6 level.

Chassis group:

The casing is a logarithmic spiral structure, welded from high-quality steel plates. The surface of the product is treated with acid pickling, phosphating or shot blasting, and then coated with plastic powder or paint.

The motor or bearing box bracket structure of each transmission mode of the fan has been optimized and designed, welded together with the casing, with a beautiful appearance, easy disassembly, and sturdy structure.

From 1600 to 2000, the upper and lower Haff structures are made along the split surface. When installation and transportation are restricted, it must be specified when ordering. The casing can be made into a structure that meets special requirements. The collector section has a nozzle shaped curve, which is formed by integral spinning and integrated with the inlet ring, making it convenient for users to connect pipelines.

Transmission group:

The transmission part adopts a CNC precision machine tool for integral boring and cutting manufacturing of the bearing box, which is composed of bearings, spindle, V-belt (coupling) transmission system, etc. Optional domestic/imported bearings and oil (grease) lubrication are available. The spindle is made of 45 # high-quality carbon steel that has been precision machined after quenching and tempering, and has sufficient safety and fatigue resistance in design.

The fan is equipped with high-quality European standard cone sleeve pulleys for easy maintenance and upkeep (the triangular belt can be optionally equipped with imported brand tapes such as Samsung according to the requirements).

Base group:

The series chassis is welded with steel sections and equipped with spring or rubber shock absorbers for seismic isolation design. The external structure is solid, compact and reliable.

Airflow range: 130-45014m ³/h.

Full pressure range: 1543-23954pa.

The fan transmission system is structurally equipped with Type A and Type D.

The fan specifications range from 2.8 to 17, with a total of 20 machine numbers.

The fan outlet can be made into seven standard angles: 0 °, 45 °, 90 °, 135 °, 180 °, 225 °, and 270 °. FAN15-G high-temperature centrifugal fan is suitable for baking ovens, drying ovens, and high-temperature gas circulation at temperatures not exceeding 280C. FAN15-G high-temperature centrifugal fan: A type fan is equipped with a special motor and a heat dissipation impeller, while C (D) type fan is equipped with a heat dissipation impeller. The basic installation dimensions are the same as FAN15, and special customization is required for temperatures exceeding 280C.

Fan structure:

Impeller group:

The impeller adopts rear curved R blades welded from steel plates, which have the advantages of high efficiency, high pressure, and low noise. Add reinforcing ribs at high speeds to increase rigidity. The dynamic balance accuracy of the impeller is ≤ 5.6 level.

Chassis group:

The casing is a logarithmic spiral structure, welded from high-quality steel plates. The surface of the product is treated with acid pickling, phosphating or shot blasting, and then coated with plastic powder or paint.

The motor or bearing box bracket structure of each transmission mode of the fan has been optimized and designed, welded together with the casing, with a beautiful appearance, easy disassembly, and sturdy structure.

From 1600 to 2000, the upper and lower Haff structures are made along the split surface. When installation and transportation are restricted, it must be specified when ordering. The casing can be made into a structure that meets special requirements. The collector section has a nozzle shaped curve, which is formed by integral spinning and integrated with the inlet ring, making it convenient for users to connect pipelines.

Transmission group:

The transmission part adopts a CNC precision machine tool for integral boring and cutting manufacturing of the bearing box, which is composed of bearings, spindle, V-belt (coupling) transmission system, etc. Optional domestic/imported bearings and oil (grease) lubrication are available. The spindle is made of 45 # high-quality carbon steel that has been precision machined after quenching and tempering, and has sufficient safety and fatigue resistance in design.

The fan is equipped with high-quality European standard cone sleeve pulleys for easy maintenance and upkeep (the triangular belt can be optionally equipped with imported brand tapes such as Samsung according to the requirements).

Base group:

The series chassis is welded with steel sections and equipped with spring or rubber shock absorbers for seismic isolation design. The external structure is solid, compact and reliable.

Product Category: Centrifugal Fan