Product Overview

Fire valves are valves used to block the passage of smoke and flames from a fire area, and to meet the requirements of fire stability and fire integrity within a certain period of time. Our company has absorbed advanced production technologies from both domestic and international sources, combined with our years of research and development on fire valves, to optimize the design and improve the airtightness and flexibility of the valve body. This product has been tested and approved by the National Fire Equipment Quality Inspection Center. When a building catches fire, the flames quickly spread along the ventilation and air conditioning system ducts, causing significant losses in many cases. In order to minimize the losses caused by fires, effective fire prevention and smoke control measures must be taken to control the spread of fire. The reasonable setting of fire dampers in ventilation, air conditioning, and smoke control systems plays an important role.

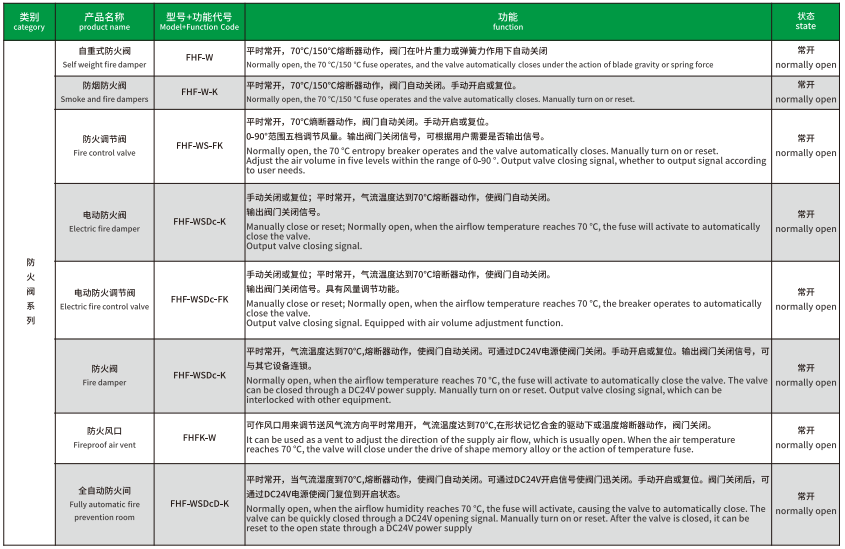

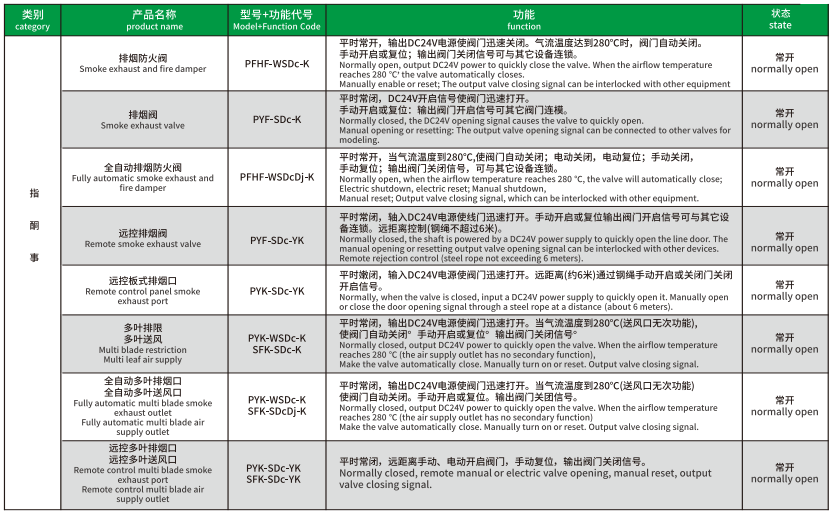

Fire damper type

Fire damper refers to a device installed on the supply and return air ducts of ventilation and air conditioning systems. It is usually in an open state, but when a fire occurs, it automatically closes when the gas in the duct reaches 70 ℃. Within a certain period of time, it can meet the requirements of fire resistance stability and integrity, and play a role in smoke isolation and fire prevention. Including various products such as gravity fire dampers, fire control valves, fire vents, airtight fire dampers, smoke dampers, electronic self-control smoke dampers, etc.

Smoke exhaust valve type

The smoke exhaust valve is used on the smoke exhaust system pipeline or the suction port of the smoke exhaust fan. It is usually in a closed state. When a fire occurs, the valve is manually or automatically opened through a fire alarm signal. According to the system function, it cooperates with the smoke exhaust. When the temperature of the smoke in the pipeline reaches 280 ℃, it automatically closes and can meet the requirements of fire resistance stability and integrity for a certain period of time, playing a role in smoke isolation and fire resistance. Mainly including smoke exhaust fire dampers, plate type smoke exhaust vents (for ceilings), smoke exhaust vents for vertical shafts, and other products. Fire dampers and smoke exhaust valves are important components in ventilation, air conditioning, and smoke control systems.

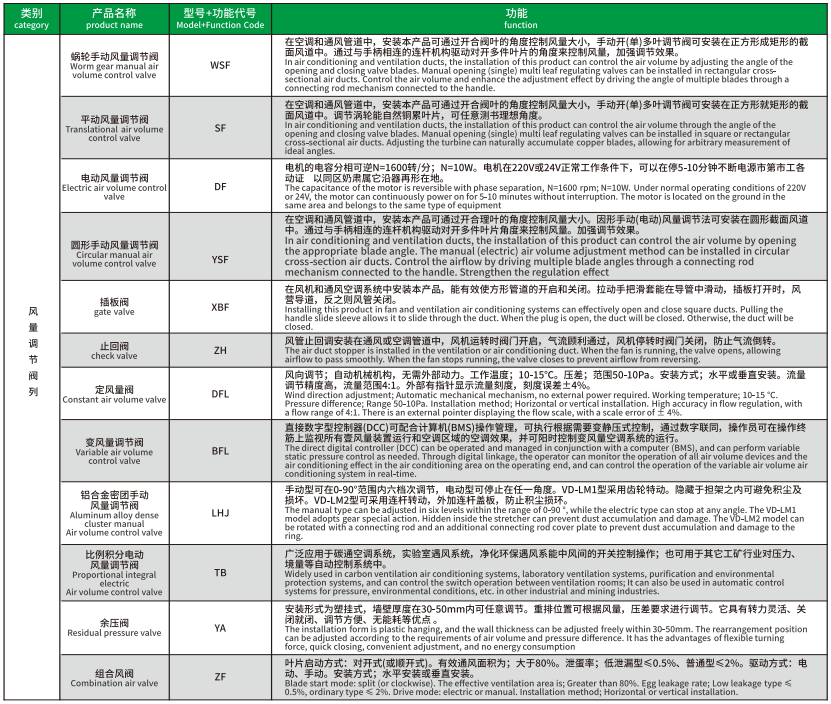

Air volume control valve

Air volume regulating valve, also known as air damper, is an indispensable central air conditioning terminal accessory in ventilation, air conditioning, and air purification projects of industrial plants and civil buildings. It is generally used in air conditioning and ventilation system ducts to regulate the air volume of branch pipes, and can also be used for mixed regulation of fresh and return air.

FHF-W self weight fire damper Galvanized sheet/stainless steel

|

SHT-ZH check valve QD-ZF Check Damper

|

Remote control smoke exhaust fire damper PFHF-WSDc-YK

|

YPYF-SDc-K Circular smoke exhaust valve

|

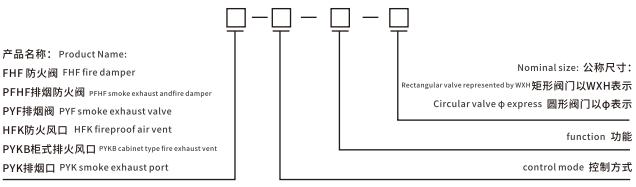

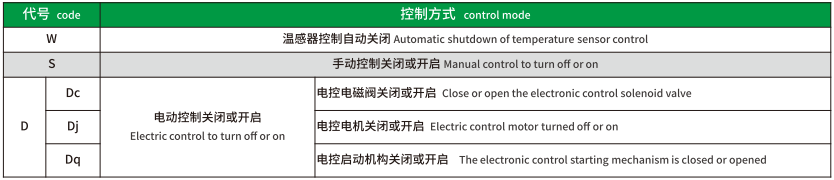

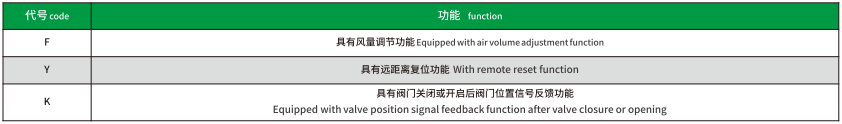

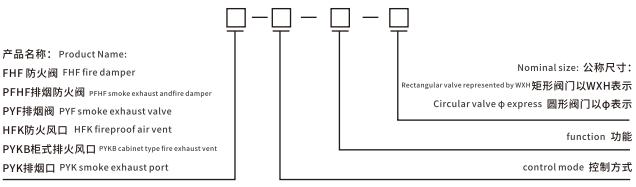

Model Description

Tag Example

Example 1

FHFWSDj-F-630 × 500 refers to a fire damper with temperature sensor automatic closing, manual closing, electric motor closing mode, and air volume adjustment function, with a nominal size of 630mm × 50mm.

Example 2

PFHFWSDc-Y-1000 refers to a smoke exhaust fire damper with a nominal diameter of 1000mm, which has automatic and manual closing of temperature sensors, closing of electric control electromagnets, and remote reset functions.

Example 3

PYF SDc-K-400x400 represents a smoke exhaust valve with manual opening, electric control solenoid opening mode, and valve opening position signal feedback function, with a nominal size of 400mmx400mm.

Installation instructions for fire damper and smoke exhaust valve series products

·Before installation, it is necessary to check the appearance quality, control performance, and valve action of the valve, and confirm that it can be used normally before drilling flange connection holes for installation.

·During the installation process, it should be ensured that the valve body does not deform, and the valve opens and closes flexibly and reliably after installation.

·The valve body can be installed vertically or horizontally, but regardless of the installation, its blades must be parallel to the ground.

·When installing valves, attention should be paid to the direction and position. The fuse (melting plate) should be in contact with the airflow before the blade shaft (i.e. on the windward side of the blade). When installing self weight fire dampers, attention should be paid to the airflow direction signs and they should not be inverted.

·Valves should be reliably fixed in the set installation position to ensure that their working performance is not affected by pipeline deformation and collapse during a fire. If necessary, lifting brackets should be installed· For fire damper with air volume adjustment, the valve opening shall be adjusted during middle note.

·When the long side or diameter of the valve body is ≥ 630mm, it must be lifted independently to avoid deformation of the pipeline affecting the flexibility and reliability of valve opening and closing.

·There should be a clear space of<200mm on one side of the valve installation operating device and the side where the spring is installed for operation and maintenance.

·Adopting a remote control operation device, the steel wire rope is protected by a 20mm refractory material tube, with a bending radius of less than 200mm and no more than three bends. The maximum length of the steel wire rope generally does not exceed 6m.